Gallery opened August 2005

Updated: 7 July 2024

Unwanted underlining in Chrome browser fixed

Powered by boiling mercury! |

Gallery opened August 2005 |

The choice of mercury for a working fluid may seem bizarre- after all, it is both expensive and horribly poisonous. However, there were what appeared to be sound thermodynamic reasons for grappling with the challenges involved in its use. After these challenges proved too great, mercury had a bit of a renaissance in projects for power plants in space. Here is the story...

There are some other working fluids which have their own galleries in the Museum:

CONTENTS OF THIS PAGE

MERCURY

Mercury has got to be the ultimate dodgy working fluid mercury: as remarked elsewhere on this site, in the Steamwheel gallery, (where mercury is used as a weight and sealant rather than a working fluid) it is an insidious poison of a most unpleasant kind. It has a much higher boiling point than water, at 357 degC. Experimental power station installations were tested in the USA but ultimately nothing came of them, the cost, complexity, and potential danger of the plant. Probably a good thing.

In a Rankine cycle, as used in steam power plants, most of the heat is supplied to boil water into steam; a major increase in cycle efficiency can only be achieved by doing the evaporation at a higher temperature. Steam has the relatively low critical temperature of 374 degC (705 degF), and a very high critical pressure at 3206 psi, so it is desirable to find a working fluid that has a critical temperature well above the metallurgical limit, and with a moderate vapour pressure at this temperature. Mercury fits the bill; it has a critical temperature of 1477 degC, (2690 degF) which is only 61 degC below the melting point of iron, and at a vapour temperature of 588 degC (1091 degF) its saturation pressure is only 300 psi.

However, the use of mercury as a single working fluid presents formidable problems. At the usual temperature of heat rejection, the vapour pressure is exceedingly low, and so the specific volume is enormous. This mean that it would be necessary to maintain an almost impossibly high vacuum in a condenser the size of a cathedral. Another snag is that mercury has a low latent heat (about one-eighth that of steam) implying that you will need a lot of it to transfer the heat in a cycle. And it is not cheap. But it is poisonous.

Therefore, to use the whole temperature range from the metallurgical limit down to the temperature of the nearest river, mercury was always used as the high-temperature section of a two-stage or binary cycle, in which condensing the mercury vapour boiled water into steam.

(Thermodynamic info from Engineering Thermodynamics: Work & Heat Transfer Rogers & Mayhew, Longmans 1957)

MERCURY IN THE NINETEENTH CENTURY

This is part of a British Association Paper called "Some of the Developments of Mechanical Engineering during the Last Half Century" By Sir Frederick Bramwell. It appeared in The Scientific American Supplement No. 312, on 24th December, 1881. While the mercury is not being used here as the working fluid (steam is) it's an interesting account of a bizarre idea.

"There was another kind of marine engine that I think should not be passed over without notice; I allude to Howard's quicksilver engine. The experiments with this engine were persevered in for some considerable time, and it was actually used for practical purposes in propelling a passenger steam-vessel called the Vesta, and running between London and Ramsgate. In that engine the boiler had a double bottom, containing an amalgam of quicksilver and lead. This amalgam served as a reservoir of heat, which it took up from the fire below the double-bottom, and gave forth at intervals to the water above it. There was no water in the boiler, in the ordinary sense of the term, but when steam was wanted to start the engine, a small quantity of water was injected by means of a hand-pump, and after the engine was started, there was pumped by it into the boiler, at each half revolution, as much water as would make the steam needed. This water was flashed on the top surface of the reservoir in which the amalgam was confined, and was entirely turned into steam, the object of the engineers in charge being to send in so much water as would just generate the steam, but so as not to leave any water in the boiler. The engines of the Vesta were made by Mr Penn, for Mr Howard, of the King and Queen Ironworks, Rotherhithe. Mr Howard was, I fear, a considerable loser by his meritorious efforts to improve the steam-engine."

"There was used, with this engine, an almost unknown mode of obtaining fresh water for the boiler. Fresh water, it will be seen was a necessity in this mode of evaporation. The presence of salt, or of any other impurity, when the whole of the water was flashed into steam, must have caused a deposit on the top of the amalgam chamber at each operation. Fresh water, therefore, was needed; the problem arose how to get it; and that problem was solved, not by the use of surface condensation, but by the employment of reinjection, that is to say, the water delivered from the hot well was passed into pipes external to the vessel; after traversing them, it came back into the injection tank sufficiently cooled to be used again. The boilers were worked by coke fires, urged by a fan blast in their ashpits, but I am not aware that this mode of firing was a needful part of the system."

The idea of using an amalgam of mercury and lead as a reservoir of heat was not a good one, and one regrets that Mr Howard was a considerable loser. The liquid with the highest specific heat, and so greatest storage capacity, is not some exotic chemical. Remarkably, it is plain water. Much cheaper and much safer!

MERCURY IN THE TWENTIETH CENTURY

The man behind the use of mercury vapour turbines in electric power stations was William Le Roy Emmet of the General Electric Company. Emmet devoted a great deal of time and energy to their development and promotion, "as a more efficient power generation system than steam turbines." The difficulties and risks in using the new technology led to termination of the development after his retirement. He died in Erie, Pennsylvania, on September 26, 1941, at the age of 82, so he had presumably managed to avoid mercury poisoning.

Mercury has a much higher boiling point than water, so the Carnot efficiency of a thermodynamic cycle that uses it is higher, in theory at least. The plants were dual-cycle, (also known as binary cycle) the hot metallic exhaust from the mercury turbines being used to produce steam for a second stage of steam turbines.

1914 Plans are made to build an experimental mercury boiler and power plant. (see below)

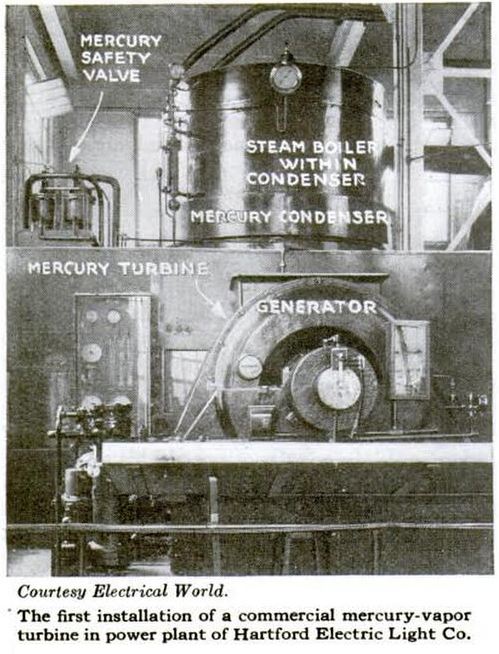

1923 The Hartford Electric Light Company (Helco) installs an experimental General Electric mercury-steam generating unit at Hartford, Conn.

1928 The first commercial mercury cycle generating unit in the world is installed at Helco's South Meadow Station in Hartford. Power output from the mercury turbine generator was 10 MW, plus the production of 125,000 lb per hour of steam at 250psi and 700 degF. According one of my sources (possibly not that reliable) the Hartford plant used 13 pounds of mercury per kilowatt generated; that would be 130,000 pounds or 58 tons, which seems like an awful lot. See Oliver Lyle's comments below.

1931 A General Electric mercury plant is installed at Schenectady, New York State, for the New York Power and Light Company. The mercury turbine output was 20 MW, plus the production of 325,000 lb per hour of steam at 400psi and 750 degF.

1933 A mercury topping cycle added to existing steam plant at South Kearney, NJ. The mercury turbine output was 20 MW, plus the production of 290,000 lb per hour of steam at 400psi and 750 degF.

1947 Construction begins on the last mercury/steam plant; the Schiller station at Portsmouth, NH.

1949 A new mercury plant at South Meadow, Hartford, begins operation on January the 2nd.

1950 The 40 MW Schiller station goes on load.

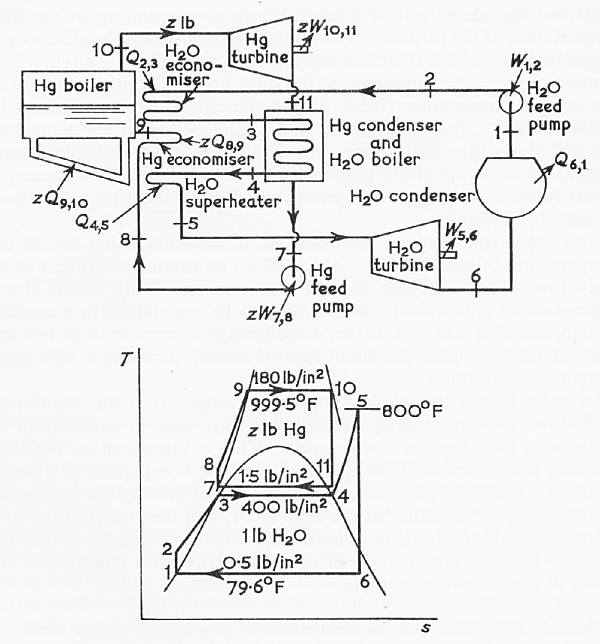

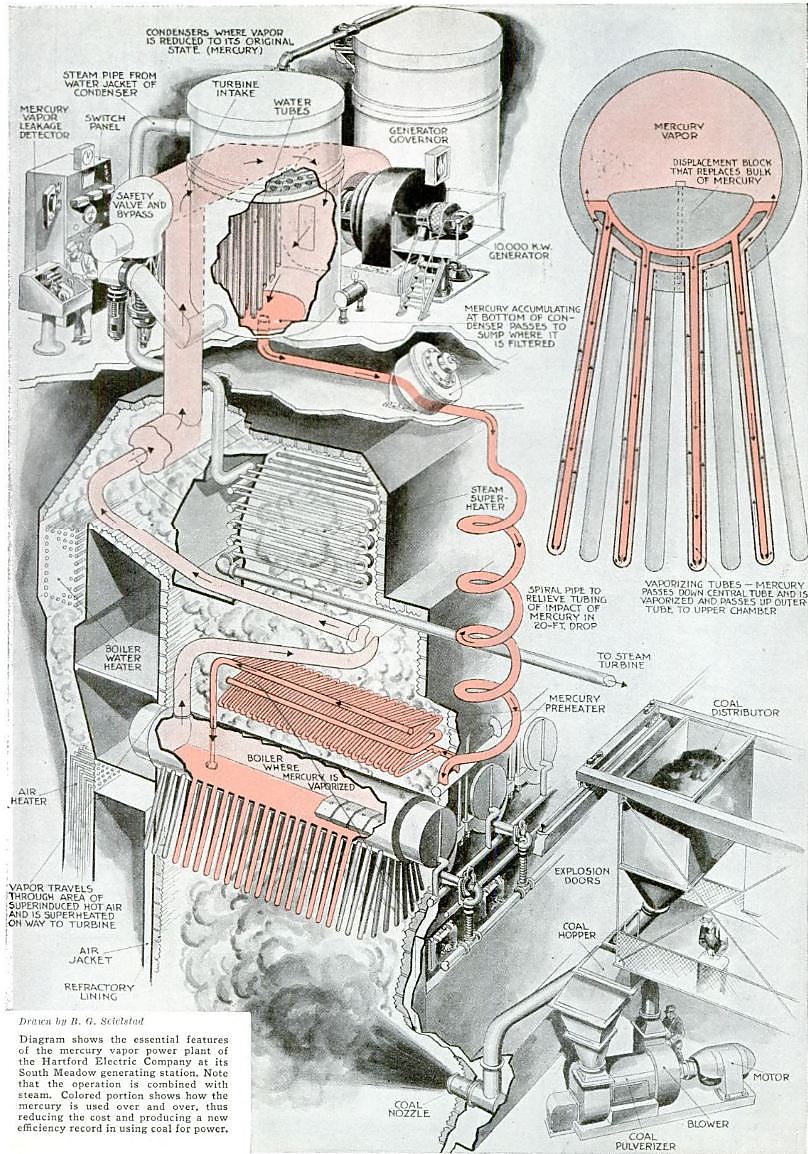

| Left: A mercury/steam power plant.

|

| Left: A mercury/steam power plant.

|

| Left: Another mercury/steam power plant diagram

|

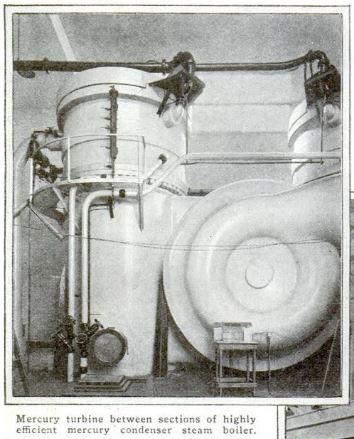

In one American plant (it is not clear which) the mercury circuit operated at 113 psi and 507 degC, driving a 15 MW turbine-alternator set at 720 rpm. The mercury condenser produced steam at 400 psi and 371 degC, at the rate of 200,000 lb/hour; this drove conventional steam turbines and alternators.

The extract below is taken from a journal that appears to have been called simply "The Tech" published by students of the Massachusetts Institute of Technology. This issue is dated Saturday, April 25, 1914.

Engineering and Scientific Notes: Mercury Turbines

"In a paper recently read before the American Institute of Electrical Engineers, there were described some interesting experiments to test the feasibility of employing mercury as the working agent in heat engines. Mercury boils under one atmosphere at a temperature of 677 degF (358 degC) and in a 28 inch vacuum it will condense at 455 degF (235 deg C). It is proposed to use the mercury vapor to drive a turbine and to utilize the heat from the exhaust in generating steam to drive a steam turbine. Despite the poisonous character of the vapor and the comparatively high cost of mercury, the liquid has several physical properties admirably suited for this purpose. Its high temperature is associated with very moderate pressure, it is clean in use and does not wet nor corrode the blades, while its high density makes possible a very moderate blade speed, an important factor. As to the question of cost, it has been estimated that the mercury would not cost more than a maximum of ten dollars per kilowatt output and, of course, the same mercury could be used repeatedly. It is claimed that a tandem mercury and steam plant would show a gain of 44 per cent on output per pound of fuel. A boiler of considerable size is now under construction in order to test such a plant on a large scale."

| Left: A later article on mercury power.

|

FROM "THE EFFICIENT USE OF STEAM"

"The Efficient Use of Steam" by Oliver Lyle, of the Tate & Lyle sugar-refining family, was the bible of steam usage in Britain during the second world war and after. It was aimed more towards process steam rather than power generation, but the sixth edition (1958) contained the following information on mercury/water binary cycles:

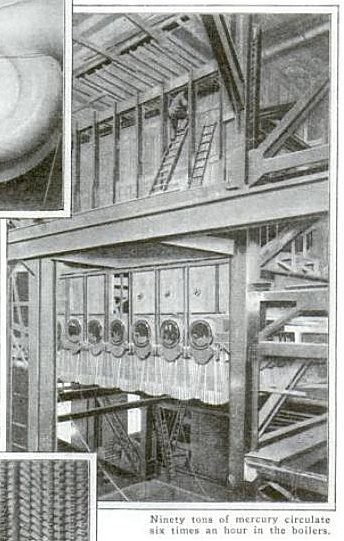

"Mercury boils at 900F under the very modest pressure of 80psi. At 28.5 in vacuum mercury vapour has a temperature of 437 degF (225 degC). If therefore, mercury is boiled in a boiler, and the saturated mercury vapour passed through a mercury turbine the mercury vapour can be exhausted into a condenser which can be a water boiler, and can raise steam to 250psi.This steam can be given some superheat up to say 600 degF (316 deg C) from the flue gases of the mercury boiler. Owing to the low latent heat of mercury it is necessary to use about 10 pounds of mercury for every 1 pound of water."

and later in the text:

"The disadvantages are somewhat formidable. Mercury vapour is extremely poisonous. Mercury does not wet metal surfaces.* The plant is complicated and costly. But several large mercury-steam stations have been working for some years in the USA and have shown very high sustained overall thermal efficiencies. other fluids might give better results. Diphenyl oxide has been suggested as being more suitable than mercury."

* If the surfaces are not wetted by the working fluid, then heat transfer would be greatly impaired. But you will see below that mercury does wet tantalum.

Now that's an interesting point above about the large amount of mercury required. And it's not cheap stuff.

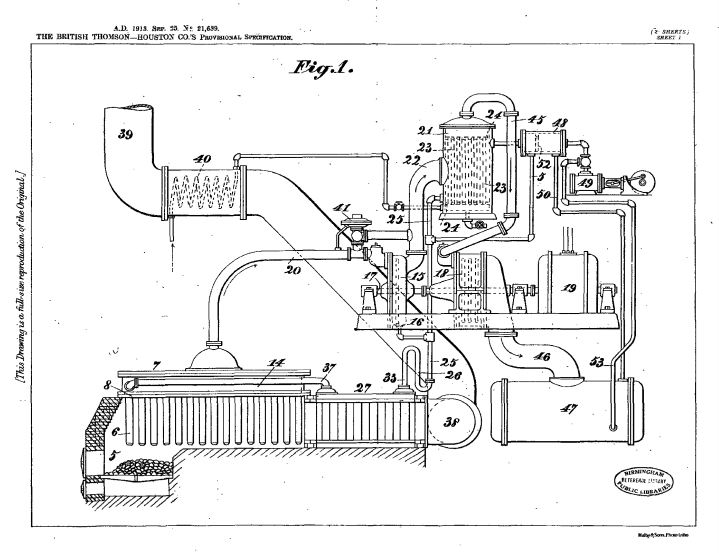

THE BRITISH THOMSON HOUSTON PATENT: 1914

In September 1914 the British Thomson Houston was granted British patent GB21689 for 'Improvements in and relating to power systems' which is an obfuscatory patent title if I ever saw one. Clearly BTH thought they has something worth hiding, insofar as you can hide a patent. The patent probably roused little interest in Europe, as there other matters going on at the time.

The British Thomson-Houston Company was the British arm of the General Electric Company of the USA.

| Left: The BTH patent of 1914

|

This is most interesting because it shows that even at this early date the technology for later plants was in place, notably the use of Field tubes in the mercury boiler, and a turbine bypass valve rather than a conventional safety valve venting to atmosphere. (The latter not being a good idea in a mercury plant)

THE DUTCH POINT EXPERIMENTAL POWER STATION AT HARTFORD, CONN: 1923

Emett first proposed the use of mercury vapour in 1914, and got the backing of T H Soren, the vice-president of the Hartford Electric Light Company. (HELCO) Following a deal with the General Electric Company, a 5000 HP experimental system was built at the company's Dutch Point generating station in 1923. The system contained a hefty 20 tons of mercury, and used mercury vapor at 35 psi, (gauge) and 812 degF to drive a single-wheel mercury turbine. The mercury condensed at 1.5 psi, (absolute) and 485 degF, and in doing so generated steam in excess of 200 psig to drive a steam turbine. To improve efficiency, the steam was reheated in the mercury boiler to about 700F.

(Info from Connecticut, the Industrial Incubator 1982, published by the History and Heritage Committee of the Hartford section of the Americian Society of Mechanical Engineers.

There were some problems; it was reported in Popular Science (March 1931) that at one point a boiler head blew out with the escape of thousands of dollars worth of mercury, only part of which was recovered. Also a turbine disc disintegrated and put the unit out of action for several months. It was stated that "workers were overcome by the fumes of the poisonous mercury. There were, however, no fatalities, nor was anyone permanently injured, because of the unusual precautions taken by the company to protect the men who had charge of the work." That does not sound like mercury poisoning as we know it, Jim. One wonders about the long-term health of the workers who were "overcome".

After this plant had been fully studied a second experimental plant was built at South Meadow, giving improved results but also suffering some problems.

Info from Popular Science Sept 1929 and March 1931

SOUTH MEADOW POWER STATION AT PORTSMOUTH, NH: 1928

In November 1928 the first commercial mercury cycle generating unit in the world began operation at Helco's South Meadow Station in Hartford.

| Left: The first commercial mercury plant installed at South Meadow in 1929

|

| Left: The two mercury-condenser/steam-boilers at the plant at South Meadow in 1931

|

| Left: The mercury boilers at the plant at South Meadow in 1931

|

| Left: The mercury part of the system at South Meadow in 1931

|

| Left: The mercury part of the plant at South Meadow as at 1949

|

The following was sent to me by Rich Colopoulos in August 2017:

"I would like to pass on some anecdotes about South Meadow Station. I was hired by Northeast Nuclear Energy Company in December of 1980 as a Mechanics Helper on Unit 2 of the Millstone Nuclear Power Station Complex in Waterford Connecticut. This is about 50 miles southeast of the South Meadow Power Station. South Meadow is located on the Connecticut River which empties into Long Island Sound which is were Millstone is located on. Some of the mechanics I worked with came from South Meadow Station after it was closed (I don't know the closing date but Unit 2 came online in the mid seventies)."

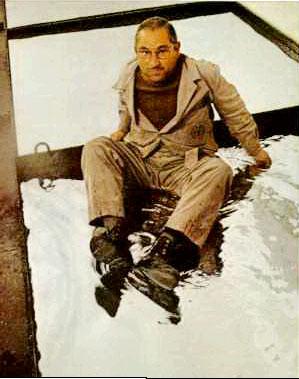

"I was assigned to help an older gentleman named Jimmy Preste who was in general just a great guy and loved to tell stories to pass the time while we were supposed to be working! He told me that they used to put wooden boards down on the mercury in the main condenser and that they would provide enough buoyancy so that could walk on them to service the condenser! I don't know if this is true but it sure is a great story and I don't know why he would have made it up, I never asked about the mercury he just volunteered the information. He and other mechanics also volunteered the ominous information that "there was a lot of mercury down by the river". I sure hope that this is not so true or that if so it has been cleaned up."

| Left: A man sitting on top of a pool of mercury: 1971

|

SCHILLER MERCURY POWER STATION AT PORTSMOUTH, NH: 1950

The Schiller power station at Portsmouth, New Hampshire, USA, was the last binary mercury/steam plant built. The site has two decommissioned GE Mercury Turbines and two B&W Mercury/Steam boilers. It currently uses three 50 megawatt coal-fired steam boilers built in the 1950s. One of these is being replaced with a fluidized-bed boiler to burn whole-tree wood chips and other clean low-grade wood materials. Read about The Northern Wood Power Project (external link)

The Schiller station consisted of two 7500 kW mercury units and one 25,000 kW steam turbine set. The rated capacity was 40,000 kW. It was equipped to run on either Bunker "C" fuel oil or pulverised bituminous coal.

I am deeply grateful to David E Corey for providing these photographs of the plant, taken in 2006.

| Left: Nameplate for the Schiller Mercury/Steam power plant

|

| Left: Mercury turbine-alternator in the centre, with mercury/steam boilers either side

|

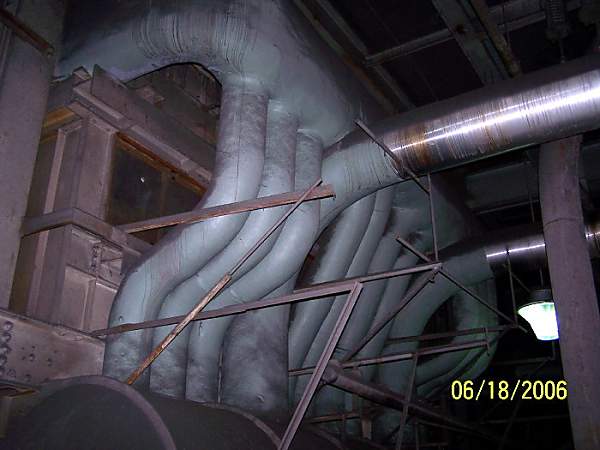

| Left: Mercury Vapor Lines

|

| Left: Mercury Drum at the mercury Boiler

|

| Left: Upper Level area in front of Mercury Boiler

|

| Left: Underneath of mercury/steam boiler

|

| Left: Mercury storage tank

|

| Left: One of the instrument panels for the power-plant

|

| Left: Nitrogen and CO2 Control Panel for Turbine Mercury Seals

|

MERCURY POWER IN SPACE: 1969

I have unearthed a NASA report from 1969 that describes a nuclear-heated mercury power plant intended to generate large amounts of electricity in space. It is called :"DESIGN AND FABRICATION OF A COUNTERFLOW DOUBLE-CONTAINMENT TANTALUM-STAINLESS STEEL MERCURY BOILER" from the Lewis Research Center, Cleveland, Ohio. It was part of the SNAP-8 program to develop a Rankine cycle power system for space applications.

The reactor is cooled with a mixture of sodium and potassium, (NaK) which heats a mercury boiler. The mercury vapour drives a turbo-alternator and is then condensed and subcooled by a secondary NaK heat rejection loop which transfers the waste heat to a radiator for rejection to space. Why is a second NaK loop used? I have no idea, but this is NASA we're talking about so I bet there was a good reason.

The report concentrates on the design of the potassium/mercury boiler, which is an exotic device indeed. It is a spiral stucture designed to fit in a small toroidal space in a cylindrical spacecraft; the heat exchanger tubes are of tantalum, which is readily wetted by mercury, making for good heat transfer. The net power output was 37 kW.

| Left: The NASA nuclear mercury turbine system.

|

| Left: The performance data.

This is one reason- possibly the most important- for the choice of mercury as a working fluid; it permits a high heat rejection temperature so the radiators are efficient, and therefore relatively small and light. |

This project was only one of several nuclear-powered sytems that were intended to provide large quantities of electricity for long-duration space missions. One of the reasons that they have not so far been used is that no-one is very comfortable with the notion of launching a nuclear reactor on top of a rocket.

You can read the full NASA report on the potassium/mercury boiler here (External link)

A word of explanation about the use of sodium and potassium alloys. (NaK) When they are between about 40% and 90% potassium by weight they are liquid at room temperature, which is very handy for a cooling fluid. The mixture with the lowest melting point (the eutectic mix), consists of 78% potassium and 22% sodium, and is liquid over the enormous range of -12.6 to 785 °C.

Another exotic heat-transfer/lubricating fluid is used in this system- polyphenyl ether, which is interesting stuff in itself, consisting of rotatable benzene rings joined by ether (-O-) links. You can read more about it here (External link)

|