Updated: 21 July 2024

More high-pressure fireless locos added

Many minor additions

Fireless Steam Locomotives |

Updated: 21 July 2024 |

A fireless steam locomotive has much in common with a conventional steam locomotive, but instead of a boiler heated by fire it has a large reservoir or steam accumulator. This reservoir is filled with superheated water under pressure from a stationary boiler. The high pressure steam above the water in the reservoir drives pistons in the usual way. As the steam is used the pressure falls, causing the superheated water to boil and generate more steam. The locomotive works until the pressure has dropped to the minimum usable level or the water is used up. The reservoir is then refilled with superheated water. The essence of this system is the superheated water that boils when the pressure on it drops. A reservoir that only contained steam would be exhausted very quickly.

There are other kinds of locomotive that do not carry a fire (apart from the obvious Diesel and electric ones)

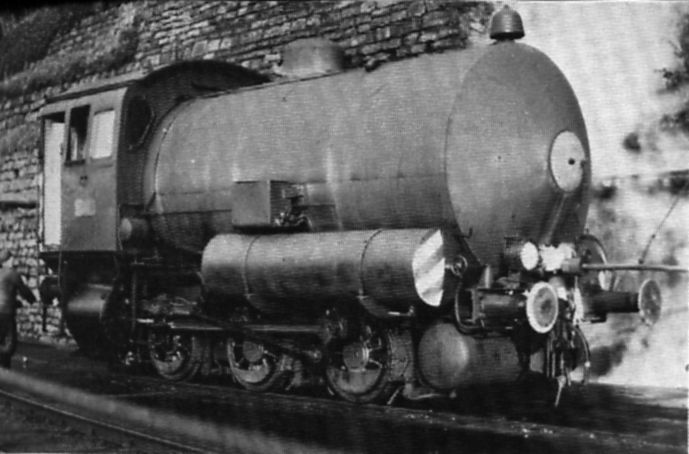

| Left: Typical fireless steam locomotive for food manufacture

|

Fireless steam locomotives were used for several reasons:

1) Where the risk of fire from inflammable gases or otherwise made a conventional firebox dangerous; typically in coal mines.

2) Where exhaust smoke was unacceptable due to poor ventilation; typically in underground railways. A classic, albeit unsuccessful example is Fowler's Ghost.

3) Where smoke deposits and cinders would have caused contamination; typically in food manufacturing plants.

4) For safety with unskilled personnel. A steam boiler will explode if the water level gets too low; they require skilled and reliable supervision. A fireless locomotive is just a tank of hot water and cannot explode.

Other advantages of the steam fireless locomotive are:

Easy to Maintain

There is no firebox and smokebox, two of the high maintenance items on a traditional steam boiler. There was no fire to clean and no ash-disposal to do. There were no boiler tubes, staybolts, grates, or superheaters on a fireless. There were very few moving parts except for the pistons and motion work. Fireless locomotives are very long-lived.

High Availability

Since the fireless runs on readily available steam from the plant it's working in, it requires very little time to start from cold. Itís available for use as soon as charged, and since this can be done during idle time, the engine is available for use practically all the time.

Quiet Operation

A soft exhaust hiss is the only sound heard from a fireless locomotive, as there is no need to direct a steam blast up a chimney. Presumably some sort of silencer could be used for very quiet operation.

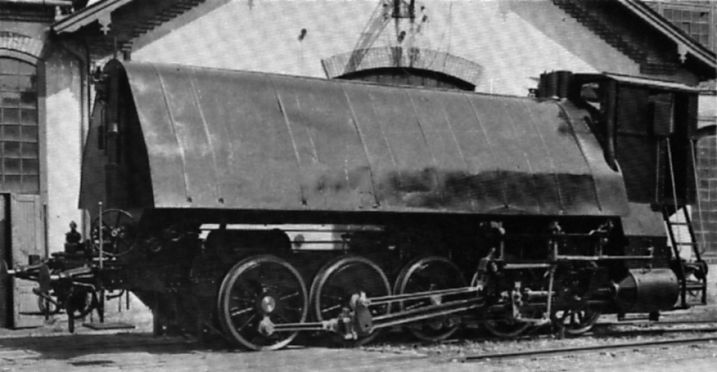

| Left: A fireless steam locomotive for chemical manufacture

|

| Left: A fireless steam locomotive for chemical manufacture

|

| Left: A high-pressure fireless steam locomotive for chemical manufacture

|

This is a remarkably high pressure, and was almost certainly only feasible because the "boiler" was just a tank, without the complication of fire-tubes and a firebox, and with little prospect of metal erosion. The highest pressure ever attempted in a real boiler on the rails was the 120 bar (1750 psi) of the Loffler-designed H02. That was not a success.

The largest builder of fireless locomotives in Britain was Andrew Barclay & Sons, who built 114 of them between 1913 and 1961.

There is more info on fireless steam locomotives in Germany, Austria, and Switzerland here. Interestingly some were used in steelworks, where you would think there was no shortage of smoke and cinders. Perhaps there was a fear of igniting blast furnace gases? Since they typically contain 5% of hydrogen, they may well ignite easily.

|