Gallery opened: Jan 2004

Updated: 21 Apr 2008

Uniflow Steam Locomotives. |

Gallery opened: Jan 2004 |

The Uniflow system was a way to improve thermal efficiency by greater expansion of the steam, without using compounding which required multiple cylinders and multiple valvegear. To learn more about the principle, see The Uniflow Steam Engine in the Power wing of the Museum of RetroTech.

There are special difficulties in using Unflow engine for road or rail transport, such as the very uneven torque characteristic during the cycle. More on that on the Uniflow Vehicles page.

The 2-2-2 locomotive "Man of Kent" was converted in 1849 to what was essentially the same Uniflow system later popularised by Stumpf. The new Uniflow cylinders were 36in long, twice the length of the original ones, and extended forwards from the bottom of the smokebox. The new pistons were 17in long. Most of the steam exhausted through a port at the centre of the cylinder; what remained when this port was closed by the movement of the piston left by the inlet valve port, preventing excess compression. It was then directed to the blast pipe by a copper pipe that ran from under the cylinders and up to the side of the smokebox; this can be seen in the drawing just ahead of the front wheel. This arrangement anticipated the "Semi-Uniflow" engines with auxiliary exhaust valves by many years.

No photographs of the locomotive exist, but there is a drawing:

| Above: The first ever Uniflow locomotive, "Man of Kent". Note the absence of balance weights on the wheels.

|

A brief account of this locomotive was given in Railway Magazine for June 1907.

ON THE NORTH-EASTERN RAILWAY.

Early in 1913 The NER (the North Eastern Railway of Britain) under Sir Vincent Raven modified an S-class 4-6-0 mixed traffic tender locomotive (No 825) by giving it two Uniflow cylinders. Piston valves were used for steam admission and also for auxiliary exhaust, so it was really a Semi-Uniflow design.

No details of its performance were ever released and no more were built; in March 1924 No 825 was rebuilt with normal cylinders. This would seem to indicate that it was somewhat less than satisfactory.

Nevertheless, Sir Vincent Raven is on record as saying that it "gave satisfaction" (that phrase again) and he was sufficiently encouraged to build in 1919 a Z-class Atlantic with three Uniflow cylinders. It was 2.5 tons heavier than the conventional Z-class Atlantics, and almost all of this extra load had to be taken by the front bogie. Once again information on performance is absent, but it was used on prestige routes so it must at least have been reliable. However it was clearly no breakthrough as in 1934 it was converted to Lentz poppet valves and was finally taken out of use in October 1945.

Like many so many attempts to improve locomotive efficiency by adopting techniques that worked well in marine or stationary installations, ultimately the results appear to have been disappointing.

In this case it is not too surprising. The Uniflow principle appeared to be a beautifully simple way of improving efficiency, but even in stationary use it bristled with practical problems. Since the central part of the cylinder stayed cooler, it expanded less; it was not unknown for the piston to seize solid in the centre of its travel. Starting a condensing stationary uniflow engine could be a nerve-racking business.

USA: D&H RAILROAD

The drive shaft for the valve gear can be seen above the cylinder.

RUSSIA

This page only deals with locomotives whose Uniflow cylinders were their most unusual feature. There are other Uniflow locomotives in the Museum of RetroTech:

The Paget Locomotive.

Above: The First NER Uniflow locomotive, No 825. Note the extra-long cylinders mounted at an aggressive angle.

Above: The First NER Uniflow locomotive, No 825. Note the extra-long cylinders mounted at an aggressive angle.

Left: The Second NER Uniflow locomotive, No 2212. On this design the three cylinders are well hidden.

Uniflow Locomotives in Other Countries.

USA: SP RAILROAD

In July 1924 a 2-10-2 locomotive (No #3769, type F-6) was built by Baldwin for the Southern Pacific railroad in the USA, and was fitted with Uniflow cylinders and Walschaerts admission valvegear, and put into in service in June 1925. The Uniflow arrangement was replaced by Caprotti valvegear in January 1931, so it cannot have been a stunning succcess. The Caprotti valvegear was in turn removed when the locomotive was rebuilt and reclassified as a standard F-5 in Feb 1937.

This was the last 2-10-2 built for the Southern Pacific.

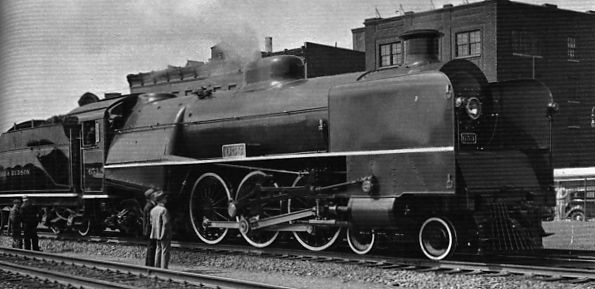

In 1931 No 653, a 4-6-2 with Uniflow cylinders and Walschaerts admission valvegear, was built for the Delaware & Hudson railroad. The conventional stayed boiler was run at a very high 325 psi, exerting a force of over 60 tons on the pistons. In 1934 it was given Dabeg poppet valvegear and new (presumably non-uniflow) cylinders.

Left: No 653 after Dabeg poppet valves had been installed.

At least one Russian locomotive was converted to Uniflow cylinders.

See Russian Reforms: The 8000 2-8-2 Opposed-Piston Steam-Diesel Locomotive of 1939.

The Swiss High Pressure Locomotive

The French High-Pressure 232P1

The Bulleid Leader

Bibliography: Perf Loco