The 232.P.1

This project was inspired by the Swiss EB3/5 High-pressure locomotive. This was tested on the network of the l'Est, and clearly impressed the observers. It was claimed that it produced 40% more work for the same fuel than a conventional loco.

The first French tests were done in 1931 (?) on a Pacific converted to resemble the Swiss machine, having a Uniflow steam-motor mounted in front of the boiler, and driving the main wheels via a jackshaft and coupling rods. No photograph of this machine has so far been found.

The view was held that a powerful and heavy locomotive was required that could not be driven by a single steam-motor, and so the final design had no less than six of them, two on each driving axle, driving the wheels through reduction gearing. Doubling the speed of a given engine doubles its power output if everything else remains constant; alternatively, you can have the same power output from a smaller and lighter engine. Another benefit is smoother driving torque from multiple cylinders.

The 232.P.1 was the result of a competition set up by POCEM to realise a locomotive without coupling-rods. In the absence of coupling rods there was nothing to equalise the work done by the motors and wheelslip was an obvious danger. The motors were therefore coupled together by a hydraulic servo system that controlled the inlet valve cams.

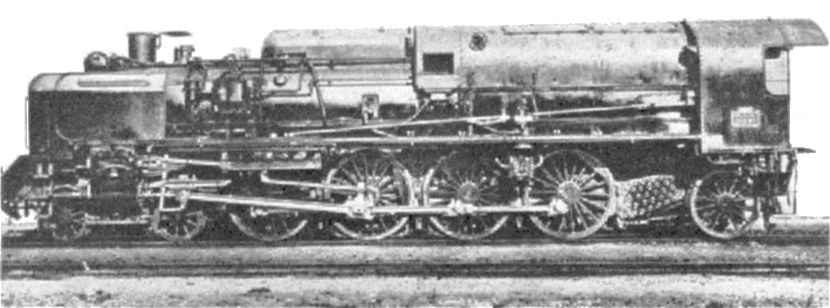

Above: The 232.P.1 was ordered in 1936, and completed in 1939. Here the fairing is removed.

Above: The 232.P.1 with part of the rear fairing in place, and supports for the front fairing added.

The locomotive was built by the SACM Graffenstaden company at the time the SNCF was formed.

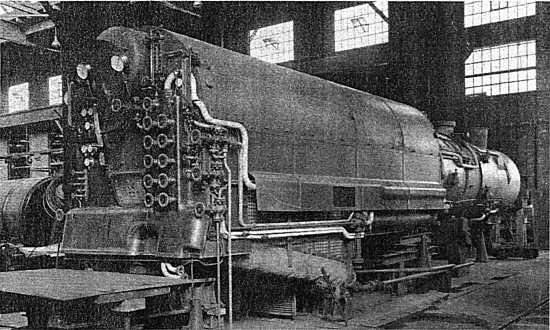

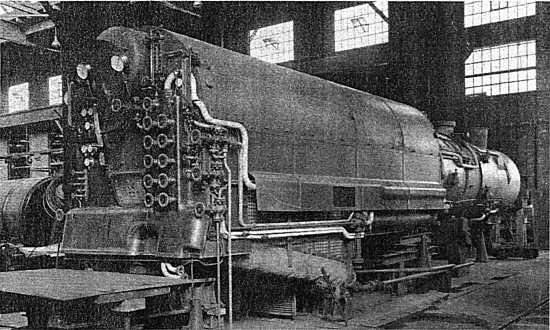

This complex machine had a dual-pressure boiler. Water from the tender passed through an ACFI feedwater heater, being raised to 215 degF. The forward LP section worked at 20 Bar, (approx 280 lb/sqin- not low pressure compared with most locos) and its hot water was supplied via dual Knorr pumps to the high-pressure boiler at the rear. Scale was to be deposited in the LP boiler, keeping it out of the HP water tubes where it would be highly dangerous. The HP boiler worked at 60 Bar. (approx 840 lb/sqin)

The two Knorr HP feedpumps were a special tandem-compound design to deal with the high delivery pressure. The Thermix injector bypassed the ACFI feedwater heater and delivered straight into the LP boiler. This suggests it was intended for emergency use to maintain safe water levels if the LP feedpump failed.

Above: The steam circuit of the 232.P.1. ACFI LP feed heater not shown

1 HP boiler 6 HP feed pump

2 LP boiler 7 Steam motors

3 HP boiler feed heater 8 Reduction gearing

4 Superheater 9 Blast pipe

5 Superheater for auxiliaries10 firebox

| | | | | | | | | |

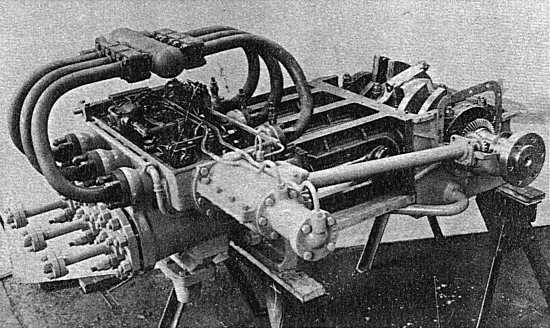

Above: Side section of one of the Uniflow high-pressure steam motors

Each driving axle was powered by two high-speed three-cylinder double-acting Uniflow steam engines, which shared a gearbox that gave provision for vertical movement of the wheels. (yes, that's a total of 18 cylinders, but small ones) The uniflow principle eliminated the exhaust valvegear but one wonders how it avoided excessive exhaust recompression, which was frequently the Achille's Heel of uniflow designs, without resorting to auxiliary exhaust valves at each end of the cylinder.

This does seem like an awful lot of complex machinery.

|

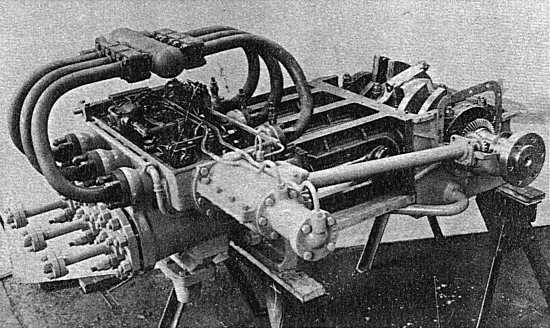

| Left: One of the Uniflow high-pressure steam motors, partly assembled.

Note how closely this resembles the uniflow engine of the Swiss HP locomotive. Admission cutoff was altered by sliding the camshaft horizontally. Nearest the camera is what is presumably a hydraulic ram for doing this. Quite how this worked without the cams jamming on the followers is not at present clear.

The curved pipes at the top supply steam to the inlet valves. Below these, but on top of the cylinders, is the transverse camshaft for operating the admission valves.

|

|

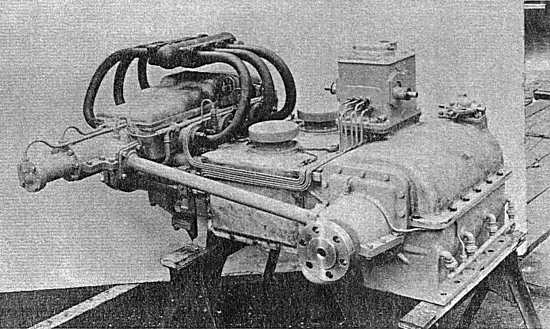

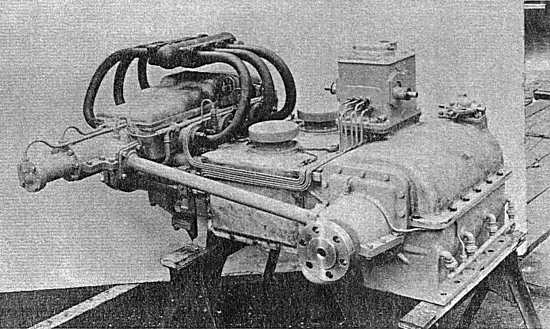

| Left: One of the Uniflow high-pressure steam motors

This time, more fully assembled. The box on top of the crankcase appears to be a lubricator.

|

|

| Left: The boiler of the 232.P.1

|

The machine was given a downright ugly streamlined fairing, and coupled to a tender of 38 m3 capacity. (No 38036)

The locomotive was given extensive trials, but was not a complete success. According to Louis Armand, inaccessibility for servicing was a major problem. The steam-motors had performed admirably, but the complex boiler system had poor performance.

In 1948 the SNCF decided not to repair it and it was rebuilt (as a conventional loco??) in 1949.

Above: The 232.P.1 with its streamlined casing in place. Not pretty, in my view.

Teach Yourself Locomotive French:

abrishelter, ie cab

aciersteel

biellerod

chaudièreboiler

engrenages gears

essieuaxle

foyer firebox

manivellecrank

rouewheel

soupapevalve

soutecompartment (eg water tank)

tablierapron, ie running board

virolering

| | | | | | | | | | | | | | | | | | | | | | | | | |

If you are researching French locomotives on the Web, bear in mind that you will have to do it in French for most of the time. You must type "chaudière Flaman" not "Flaman boiler" into Google if you want results. And you must get the accents right; ignoring them just won't work.