It seems pretty clear that the best shape for a reciprocating piston is a cylinder. But has that stopped people trying other shapes? Oh no. Here is the strange world of square or rectangular pistons; the Dake engine was actually rather successful in niche applications.

THE ROOT ENGINE

|

| Left: Roots Square Piston Engine: the principle

John B Root was granted US patent 39,957 for this engine in September 1863. He had previously taken out a very implausible patent (US 14778, 1856) for a rotary steam engine, in which cylindrical rollers rotated in a sort of rubber bag.

"The oblong square box,A, is the cylinder proper. b is a frame sliding freely in a horizontal direction by the force of the steam from the side ports, d,d. C is the inner rectangular piston, connected directly to the crank pin a, the shaft b, being central to the range of the moving pistons. The piston C receives steam from the top and bottom ports, d,d, within the frame B."

Quote from "Mechanical Movements, Devices and Appliances" by Gardner D Hiscox, published by Sampson Low, Marston & Co, 1899. The part of the caption that is in quotes is taken from this book.

|

A rather strange idea, and one would not have been at all surprised if it vanished without trace. But... see the Dake engine below.

|

| Left: Roots Square Piston Engine: internal workings

The large piston E moves horizontally. The smaller piston F moves vertically inside E.

T is the cover plate for the engine, incorporating a circular valve-box I, closed by a plate screwed over it. Steam is supplied via the valve K at the top, and passes to the valve-box by a passage not visible here. It enters the "cylinders" via ports G when they are uncovered by the valve disk X. The exhaust leaves through the same ports and enters the annular channel M and escapes through the passages shown dotted, which feed into a common exhaust duct.

The valve-plate X is fitted to an eccentric L on centre-pin D, and is carried round by a pin S on the end of the crank, so that it rolls around the inside of the circular valve-box, opening and closing the ports as it passes.

From Knights American Mechanical Dictionary, 1880.

|

THE DAKE SQUARE PISTON ENGINE

|

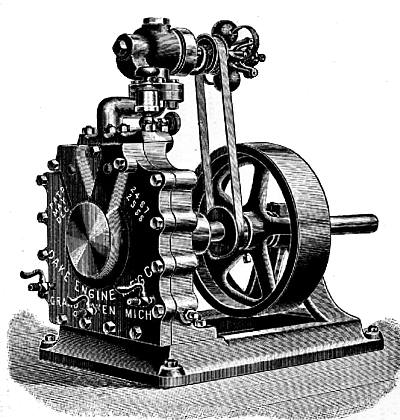

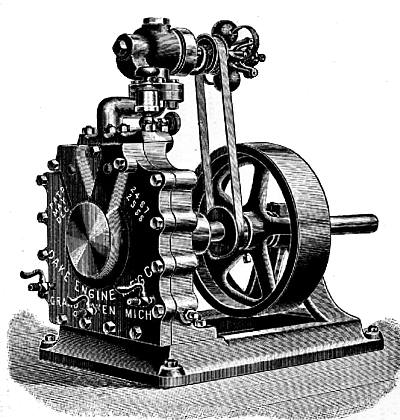

| Left: Dake Square Piston Engine: 1888

This engine by William Dake was granted US patent 395,039 in December 1888. The Dake engine may have been unusual, but it actually had some success over a long period, because of its compactness, lack of dead centres, and ease of reversing.

"Two rectangular pistons, one within the other, working at right angles in the outer piston. The inner piston is connected to the crank pin, and moves vertically. The outer piston moves horizontally in the case. The principal is similar to the Root Square Piston Engine." says Gardner D Hiscox.

Or to be more accurate, the principal looks spot-on identical. I think we know where William Dake got his inspiration. All praise to him for making it work, though.

The engine shown here has a horizontal ball-governor mounted on the steam valve, and belt-driven from the output shaft.

Quote from "Mechanical Movements, Devices and Appliances" by Gardner D Hiscox, published by Sampson Low, Marston & Co, 1899.

Picture from Cassier's Magazine, October 1896; kindly provided by Craig Crouch.

|

My information is that this engine was put into production, by the Dake Engine Company of Grand Haven, Michigan, in 1887. That puts it before the granting of the patent, which seems a tad premature.

|

| Left: The Dake Square Piston Engine animated.

Showing how the inner piston moves inside an outer sliding piston.

Another stunning animation by Bill Todd.

|

Charles Dockstader's website has a program you can download that shows an animation of the Dake valvegear.

|

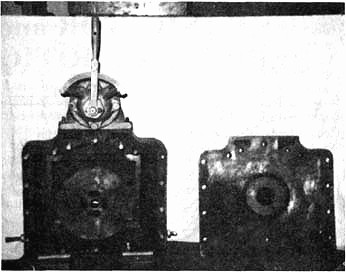

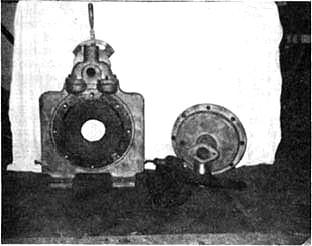

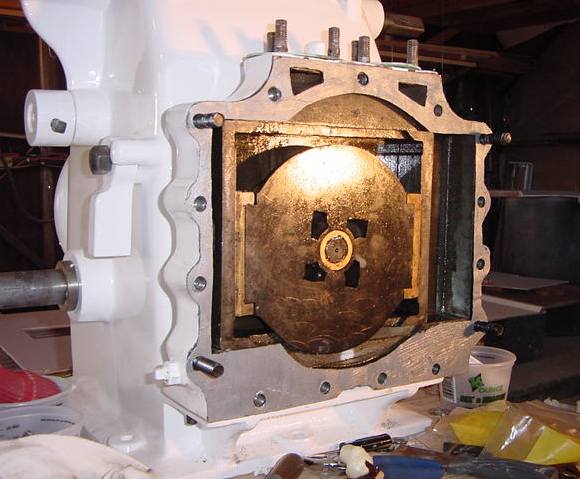

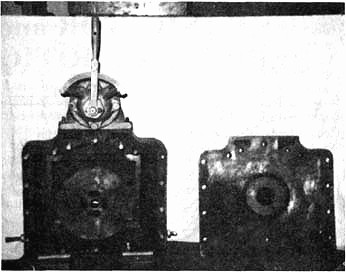

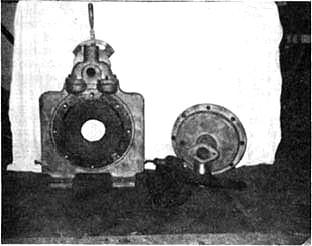

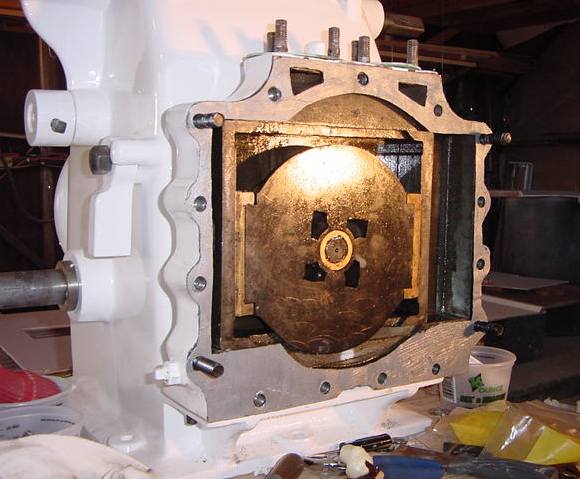

| Left: Dake Square Piston Engine.

Against all the odds, some pictures of this extremely rare engine have been unearthed. This example belongs to Randy E. Schwerin of Iowa.

He says: "The first picture shows the "square piston" in place, and the internal surface of the cover with parts exposed. Proper clearance at this point is critical as this determines the end clearance of the piston itself. Therefore attention must be paid to the thickness of the gasket used." Note the reversing lever at the top of the casing on the left.

From an article written for the US magazine Steam Traction by Randy E. Schwerin of Iowa in 1983. All attempts to contact Mr Schwerin or the editor of the magazine via the internet have failed, so I am showing these pictures as they are too precious to be lost. If anyone feels their copyright has been infringed then please let me know.

|

|

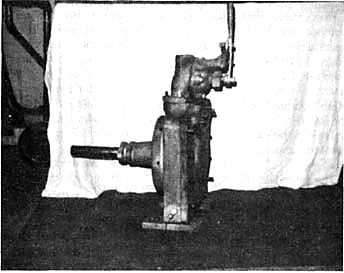

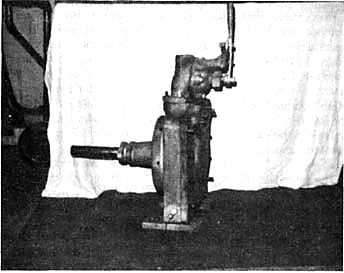

| Left: Dake Square Piston Engine.

The Dake engine pictured is a 3.5 HP size. The photograph shows the opposite side of the engine with crank shaft and cover.

From the article by Randy E. Schwerin, 1983.

|

Randy Schwerin first encountered square pistons on a big Reeves traction engine, which used a small Dake engine as the power steering device. He says: "The engine steers the Reeves well at any pressure over 100 p.s.i. which says a lot for the power of it, as the Reeves weighs 27 tons. I would guess the little Dake to be 1.5 or 2 HP, with a 1/2 inch steam inlet and 3/4 inch exhaust. It weighs approximately 100 pounds.

"Basically, all that was required was a good cleaning to remove the surface rust that had accumulated on the internal parts and to resurface the controlling valve. Upon assembly and after hooking to live steam it ran smoothly and noiselessly with no dead centers, and reversing instantly upon changing the position of the control lever."

|

| Left: Dake Square Piston Engine.

This shows the engine assembled.

From the article by Randy E. Schwerin, 1983.

|

|

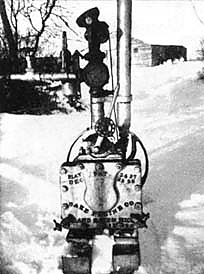

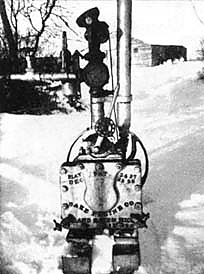

| Left: Dake Square Piston Engine.

This Dake engine belongs to Ed Richards of Saskatchewan, Canada.

He says "Steam at 100 psi is used to bear against a piston surface area 2"x7" and with a stroke of 2", (the engine) develops approximately 5 HP. This engine was used for pumping water into the tender of a large traction engine. With the piston being rectangular it requires careful shimming to achieve a satisfactory steam seal between the piston and the block."

From an article written for the US magazine Steam Traction by Ed Richards in 1973. As with the other pictures above, all attempts to contact Mr Richards or the editor of the magazine via the internet have failed, so I am showing these pictures as they are too precious to be lost. If anyone feels their copyright has been infringed then please let me know at once.

.

|

|

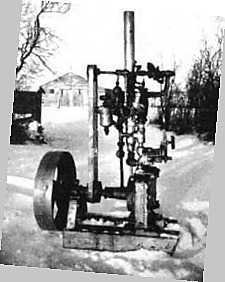

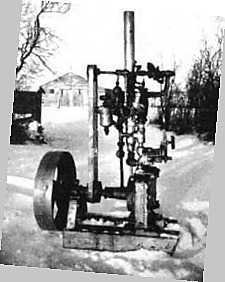

| Left: Dake Square Piston Engine.

It seems pretty clear that sealing was an issue, with some critical assembly required to get a good seal. These engines appear to have only been used in small sizes and intermittently. The sealing losses in a large engine would probably have been excessive.

From the article by Ed Richards, 1973.

|

|

| Left: A steam forklift with a Dake engine.

An ancient steam forklift, with what is clearly a Dake engine snuggled up to the base of the boiler. The operator's seat is at the extreme lift; the crank next to it is for steering by rotating the wheel under the suspension spring. The actual lifting part seems to be missing.

The compact design of the Dake engine is seen to advantage here.

Provenance of picture unknown. If you think I have dissed your copyright, please let me know.

|

Dake engines were also used for hoisting. From an interview conducted in a study Michigan local history:

"The old Dake Engine Company, in its early days, that was known for making hoist

engines for ships, that, you know, the cargo hoist engine, and it was a square piston

engine that they built, and they still maintained parts for that for years after that because

those engines were so good and so reliable, all they needed were sometimes new pistons

or new rods or something like that..."

Since one thing that Dakes engines did not have was piston rods, the interviewee was clearly no Dake expert. See here for the full interview. (external link)

|

| Left: A Dake-powered steam windlass under restoration.

This picture was sent to me by Stephen Cobb, who says:

"I thought that you might be interested that we have restored and reinstalled an 1898 Dake/Box anchor windless on the 126' steam yacht

Cangarda. Attached is a photo of the square piston as mounted on the Box windless.

At ABS/USCG trials, the engine and windless successfully handled a 350# anchor and 150' of chain in a bottomless lift. It works

beautifully and has plenty of power and speed. This engine and windless have been operational since the yacht was built by Pusey &

Jones in 1901. Cangarda is still a steamer and has 6 other steam engines built by Sullivan or Davidson. We replaced the old Almy boiler with a modern express water tube, oil fired boiler."

More pictures of the steam yacht Cangarda can be seen on Flickr.

Picture kindly provided by Stephen Cobb

|

|

| Left: Dake engine owned by Allan Dake.

This picture was sent to me by Allan Dake, whose great-grandfather's brother was William F. Dake. It is a Dake #3-1/2 engine, rated at 7 HP. It was built in 1917 and installed in the Ford Motor Company Saw Mill in Pequaming, Michigan.

Note that this engine looks very similar to the drawing on the cover of the pamphlet below, rather than the older designs above; in particular it does not have the corrugated outline to the main body. This leads me to suppose that this is a relatively modern version. It displayed at the Muskegon Heritage Museum, where it runs on 100psi compressed air, though there are plans to run it on steam.

|

THE DAKE ENGINE COMPANY

The Company was founded in 1887.

A special feature in the The Evening Tribune, July, 1891 of Grand Haven, Michigan, refers to

"the celebrated Dake engine" and continues thus:

"DAKE ENGINE WORKS.

The most popular engine now in use for many classes of work is the Dake, invented by William F. Dake of this city, and together with other inventions of Mr. Dake, manufactured by the Dake engine Company. The plant has been in operation about four years and has a capital stock of $100,000. They turn out more than an engine a day upon an average the year around. The company has patents in this and other countries valued at $50,000. These engines are much more compact than any other engine made and may be reversed with lightning rapidity. They are adapted to all uses where steam is required, and the sales upon them are rapidly increasing. The officers of the company are Thomas Cairns, president, and James P. Armstead, secretary and treasurer. The company has a monthly pay-roll that contributes largely to the prosperity of Grand Haven."

See here. (external link)

Well, that states pretty plainly that the Dake engine was invented and patented by William F. Dake, though it is clearly not an impartial source. Did he copy Mr Root's design, or were they parallel developments?

According to The Eighth Annual Report of the Michigan Bureau of Labor and Industrial Statistics, the

Dake Engine Mf'g. Co. had 16 employees in 1890.

In 1940 the Dake Engine Company, was purchased by

Jacobson-Johnson-Sherwood, (external link) but engines were apparently still being manufactured at Grand Haven, Michigan until the Fifties at least.

|

| Left: The front cover of an advertising pamphlet for Dake engines.

Engines are now offered for either air or steam operation. The pamphlet is undated but from the style of its illustrations, dates from the late Fifties or early Sixties.

I have unconfirmed information that engine production finally ceased in 1987, a hundred years after it began in 1887. Not a bad run!

Remarkably, the Dake company still exists: see www.dakecorp.com. It now makes machine tools.

Pamphlet kindly supplied by Charles P Reiter, who tells me that there is another Dake engine owned by a collector in central California. It is restored and is run for demonstrations.

|

THE ELVIN STOKER ENGINE

The Elvin Stoker was a machine for firing steam locomotives. Coal in the tender was broken up, passed forward by a screw conveyor, and thrown into the firebox by mechanical shovels. Mechanical firing was relatively common on big USA locomotives; here our interest is focused on the little steam engine that drove the stoker. The information here comes a comprehensive little book called the Elvin Mechanical Stoker Road Service Handbook.

|

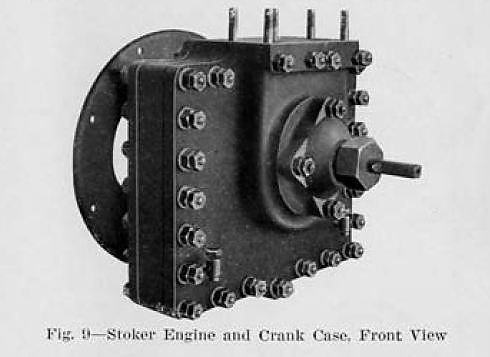

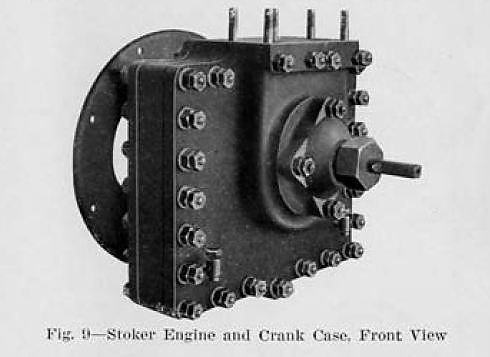

| Left: The square-piston engine that drove the Elvin Stoker

There appear to have been two of these engines; one in the tender, driving the coal-breaker and screw, and this one on the locomotive driving the mechanical shovels; note the fixing flange to the left.

From the Elvin Mechanical Stoker Road Service Handbook. Date unknown but circa 1930

|

|

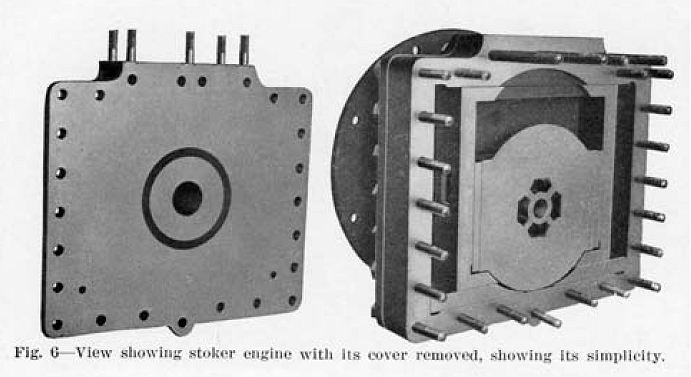

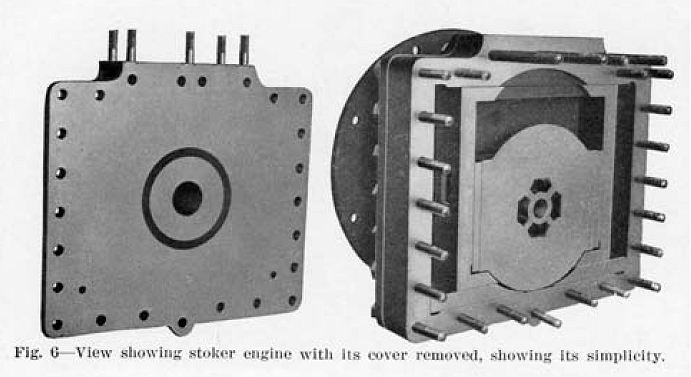

| Left: Inside the square-piston engine that drove the Elvin Stoker

Now this looks awfully like a Dake engine. However Dake is never mentioned at any point in the Elvin handbook. The engines may have been made under licence or simply bought in. Their compactness made them ideal for this application.

From the Elvin Mechanical Stoker Road Service Handbook. Date unknown but circa 1930

|

Some more info on the Elvin stoker from the Locomotive Cyclopedia of American Practice, published by the American Railway Master Mechanics' Association. (6th edition, 1922) I quote:

"The problem of engine design to give a simple, compact, efficent and economical unit for driving the Elvin Mechanical Stoker was met by the use of the novel double-reciprocating rectangular- piston engine... The engine is rated at only 6 hp at 100 psi steam pressure and it has been found more than ample to meet the power requirements of the stoker, feeder and crusher.Normally it uses but 30 psi or about one third of full rated pressure. This engine has no dead center and can be started, stopped, or reversed instantly by means of a convenient throttle and reverse lever. There are no eccentrics, and there is not a bolt, nut, or piston ring inside the casing. It requires less space than any other steam engine of equal power and stands the strain of long and strenuous use..."

|

OK, it's a good engine, but was it a Dake? There is no clue in the text, but in a diagram on page 380 a part is labelled 'Crank case Dake engine'. So that settles that.