Gallery opened 13 Dec 2018

Updated: 19 June 2020

More on the Cecil engine

Links added

A difficult fuel

Hydrogen Engines |

Gallery opened 13 Dec 2018 |

Many inflammable substances have been used as fuel for internal combustion engines. Petrol, paraffin, coal gas, blast-furnace gas, and even powdered coal have been used. It has to be said that the last mentioned was unsuccessful despite strenuous efforts by many talented engineers.

Missing from the list is hydrogen, well-known for its ease of ignition and explosion. At first sight there is not much need for a hydrogen engine as hydrogen is not mined and is relatively expensive to make from other chemicals. There is however, one environment where an excess of hydrogen can be an embarrassment- in an airship.

HYDROGEN AS AIRSHIP FUEL

If your airship is too heavy and dropping, you simply drop some of the ballast that you thoughtfully brought with you; this is fine until you run out of ballast. If your airship is too light, perhaps because sunshine has warmed your hydrogen, you can let some out through valves; once again you can only do so much of this. The airship will also become lighter as the fuel is consumed.

It would be more efficient to not just throw the hydrogen away, but use it as a fuel in the engines- that would reduce the amount of ordinary liquid fuel you would need to take off with, and so improve your payload.

I now hand over to Nevil Shute Norway, one of the designers of the successful R100 airship. In his autobiography Slide Rule he says:

"It seemed necessary to design a special airship engine that would run on kerosene and hydrogen drawn from in the gasbags, to maintain the ship in equilibrium; all this had to be thought out and put in hand, and the experimental engine built." (Slide Rule, pub Heinemann 1954, p60-61)

"At first it seemed expedient to design a special engine for R100 running on hydrogen and kerosene. After a year's work it became evident that this engine would not be fully developed before it was required for installation in the ship. The work was stopped, the design and work in progress was sold off in the most economical way..." (Slide Rule, p75) |

We now turn to the famous engineer Harry Ricardo, who ran the foremost IC engine design consultancy in Britain; it was he who designed the first effective engines for WW1 tanks. In his autobiography Memories and Machines he says:

"Attempts had long since been made to use the surplus hydrogen as a fuel by admitting it to the carburettor of the petrol engines used for our small airships during the war, (WW1) but it had been found that the addition of even a very small amount of hydrogen provoked violent detonation. During our research on the use of a stratified charge we had observed that the range of burning in a petrol-air mixture could be extended enormously on the weak side by the addition of a little hydrogen and that without any trace of detonation, so long as the petrol-air mixture was diluted with so large an excess of air that ignition from the spark plug would be impossible.""...On the strength of these test results which extended over about two years we were asked to prepare a scheme design for a sleeve valve hydrogen-kerosene engine of about 550 BHP at a speed of 1000 to 1100 rpm, and a maximum bmep of about 60 psi. This was a fascinating exercise. Owing to the low mean pressure the total cylinder volume would need to be at least double that of a petrol engine of equal power and speed. On the other hand, the maximum cylinder pressure would only be about 250 to 300 psi as compared with about 600 psi in the petrol, and probably nearly 1000 psi in the diesel engine; thus we could safely employ much lighter scantlings and working parts. Again, the whole cycle temperature would be so much lower that we need hardly worry about thermal stresses, and in short the design problem resembled much more nearly that of a steam rather than an internal combustion engine. After much deliberation we prepared a scheme for a six-cylindered in-line engine of 10 inches bore and 12 inches stroke... For the hydrogen supply we provided a small three-cylinder radial compressor running at crankshaft speeds..." |

Another extract from Memories and Machines

"...During the design stage we were in close touch with Barnes Wallis who was always most helpful, and we all came to look upon him as a tower of common-sense, sound judgement and ingenuity. However, as time passed, he became too pre-occupied with other aspects of the problem, to pay much attention to a long-range engine development, for it had been decided that the R100 would be propelled by Rolls-Royce Condor petrol engine isthe first instance, to be replaced later by hydrogen-kerosene engines if and when they proved a success."We were instructed by the Airship Guarantee Co to prepare a complete design and detail working drawings... and at the same time, Brotherhoods were given a contract to build a prototype engine to our design. We set to work with enthusiasm on what promised to be a thrilling task; little did we realise into what a hornet's nest of politics and intrigue we were entering." "...At long last our hydrogen-kerosene engine at Brotherhoods was completed and put on test but without all the duplicated accessories. Rather to my surprise it performed quite well in that it developed the power expected of it but its fuel consumption was rather high. On stripping it down after the test it was obvious that the distribution of fuel between the cylinders was very uneven and that the fuel and hydrogen injectors were not giving a fine enough spray, with the result that a large amount of liquid kerosene had found its way into the crankcase. There were also several other mechanical defects and it was obvious that a lot of patient development work lay ahead." "Thus far we had got when the terrible disaster to the R101 brought the reign of the rigid airship to an end. ...All further work on our hydrogen-kerosene engine was abandoned, to our intense relief. What had started as a fascinating technical problem had become so bedevilled with politics that we were thankful to be quit of it." |

LIFT COMPENSATION IN AIRSHIPS

The problem of an airship getting lighter as fuel is used can be avoided by using a gaseous fuel with the same density as air. One or more of the gasbags is used to carry this fuel, and as it is used up its volume is replaced by the same amount of air. This sytem is called lift compensation or . It was used on the LZ 127 Graf Zeppelin, a highly successful airship that made 590 flights totalling more than a million miles before it was scrapped in 1940 so its duralumin airframe could be melted down for military aircraft production.

The secret to the success of the system was the use of blau gas as fuel; this had approximately the same density as air. Blau gas was an artificial illuminating gas named after its inventor, Hermann Blau. Blaugas contained about 50% olefins (alkenes), 37% methane and other alkanes, and 6% hydrogen, with the remaining 7% being air. It was mainly used for lighting and heating; it had the highest specific energy of all the artificial gases, but unlike producer gas and coal gas, it did not contain deadly carbon monoxide.

Why did the British not use this system? One drawback is that having one or more gasbags full of fuel with the same density as air reduces the lift available. However it seems that the British may not have been aware of the German technology.

From Harry Ricardo on the fuel question:

"Of the possible gaseous fuels available at that time ethylene appeared to be almost the only choice and we therefore carried out tests on this gas in our variable-compression engine but found that, like methyl alcohol and ether, it had a dangerous tendency to pre-ignition even at very low ratios of compression which put its use out of court." |

THE EARLY HISTORY OF HYDROGEN ENGINES

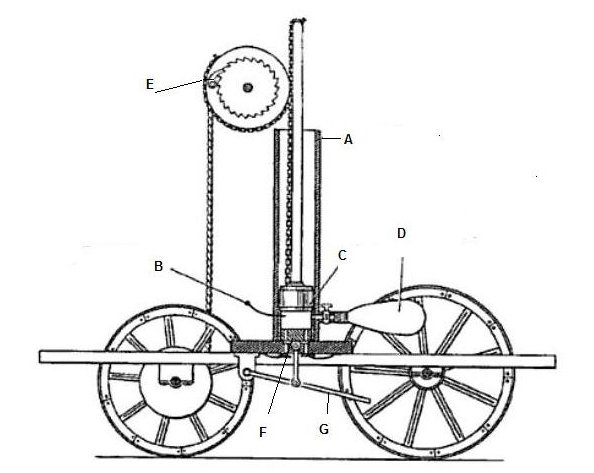

| Left: The Rivaz engine and vehicle: 1807

|

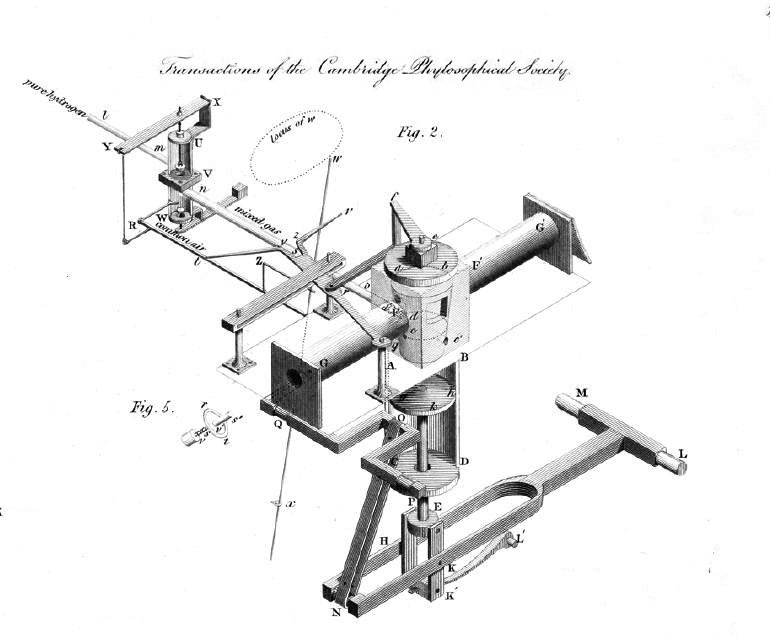

| Left: The Cecil hydrogen engine: 1820

|

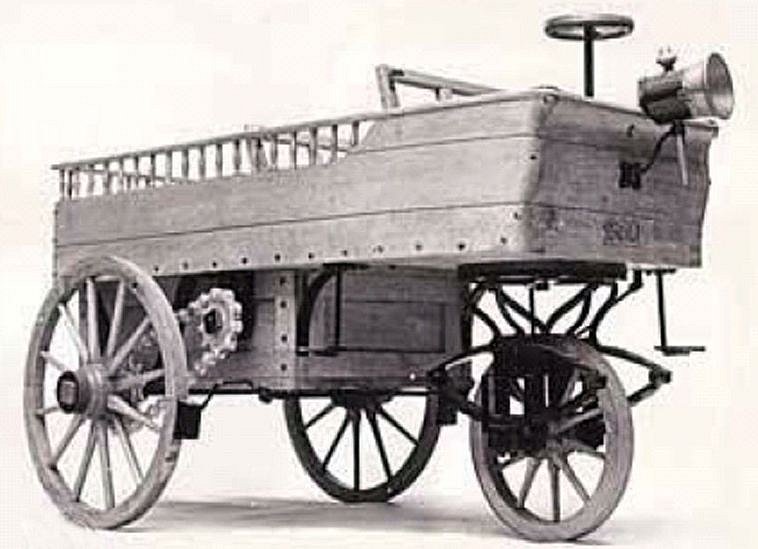

| Left: The Lenoir Hippomobile

|

HYDROGEN ENGINES ON THE WEB

The website of hydrogencarsnow.com gives details of many hydrogen vehicles, starting with Rivaz in 1807. None have been investigated so far by the Museum Staff. It is a mystery why the page makes no mention of the detonation problem.

There is a Wikipedia article on hydrogen IC-engine vehicles.

Also one on hydrogen vehicles in general, which includes just about every sort of vehicle from bicycles to rockets. However many of these use hydrogen to power fuel cells eather than fuel IC engines. We are not concerned with fuel cells here.

DISADVANTAGES OF HYDROGEN ENGINES

|