Gallery opened: 29 April 2015 |

Helium engines

|

Gallery opened: 29 April 2015

Updated: 12 July 2024

Helium purification info added here.

The main reason to make a helium engine is to liquefy helium efficently, though there is some interest in helium-cooled nuclear reactors. As for liquid air, using an expansion engine rather than a Joule-Thomson throttle valve to drop the gas pressure, as in the Linde cycle, gives more efficient cooling because work is being taken out of the system. A further complication fully explained in the link is that a gas must be below its inversion temperature to be liquefied in this way, and so simple Linde cycle liquefiers cannot normally be used to liquefy neon, (BP -246.1 degC) hydrogen, (BP -252.9 degC) or helium (BP -269 degC) and the use of an expansion engine is then essential for reasonable efficiency.

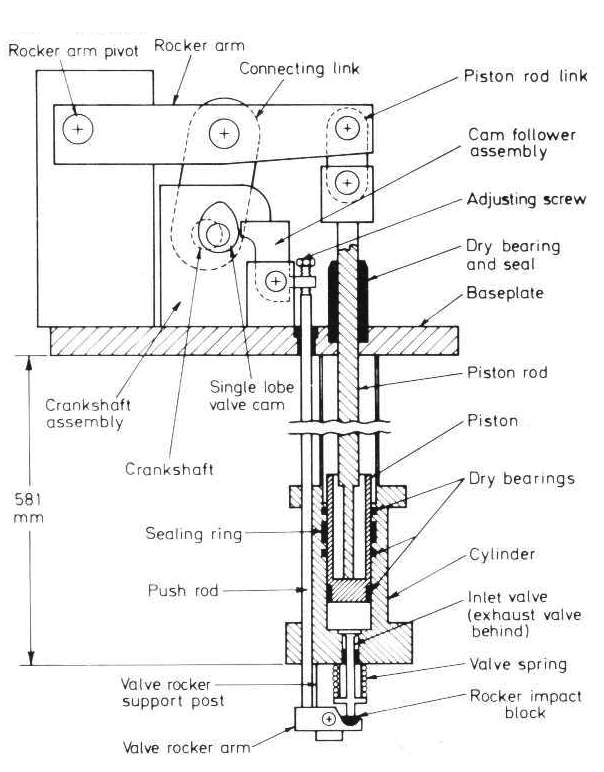

| Left: Helium piston engine for wet expansion

|

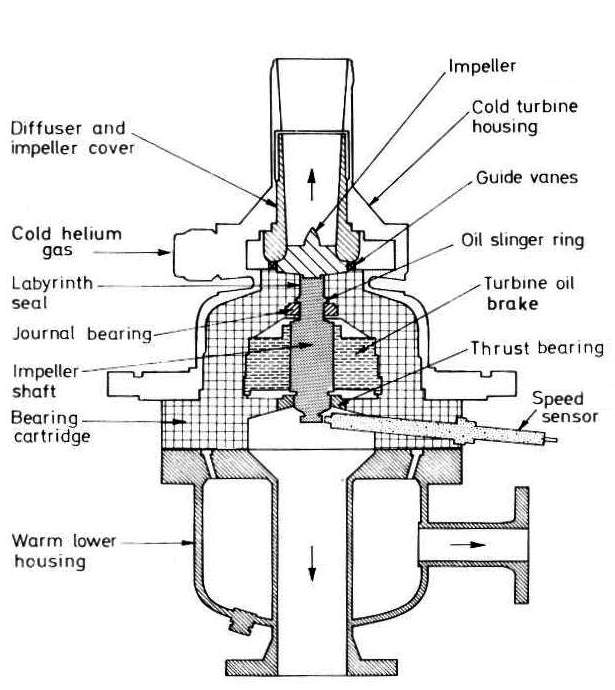

| Left: Section through a helium turbine

|

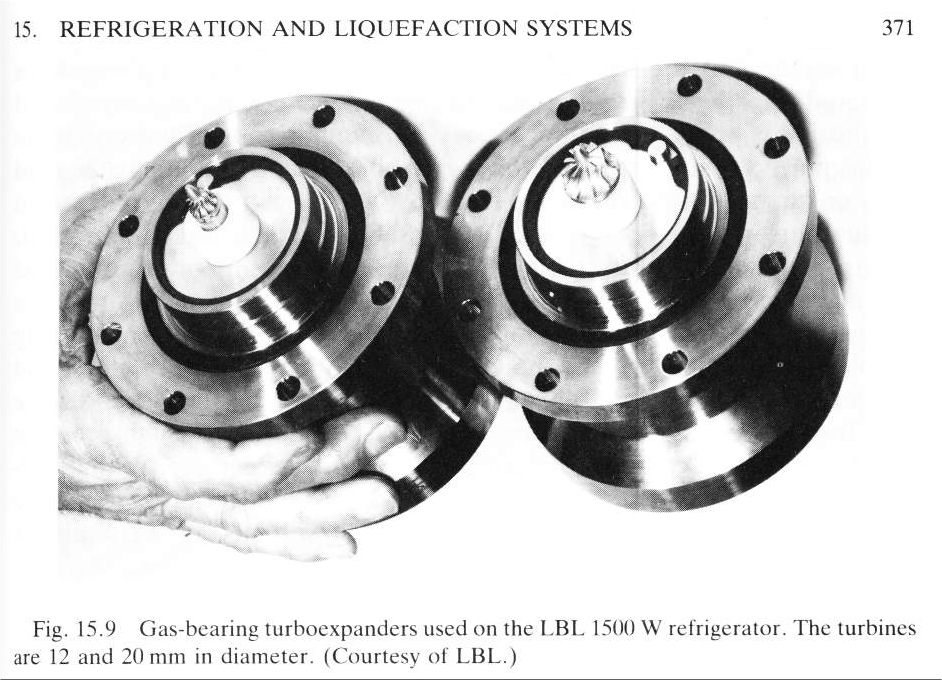

| Left: Two helium turbines of different size

|

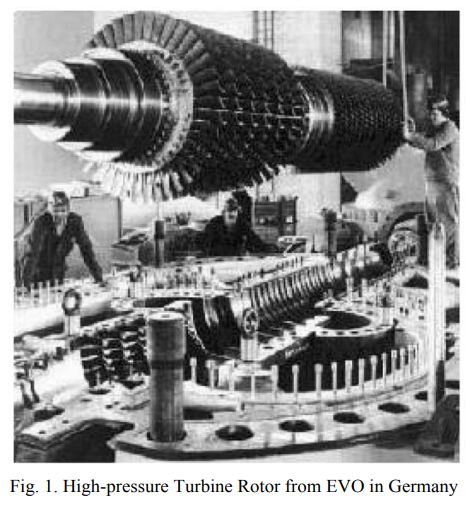

| Left: The helium HP turbine of the HHT test system: Germany

|

Helium-cooled reactors have a Wikipedia page.

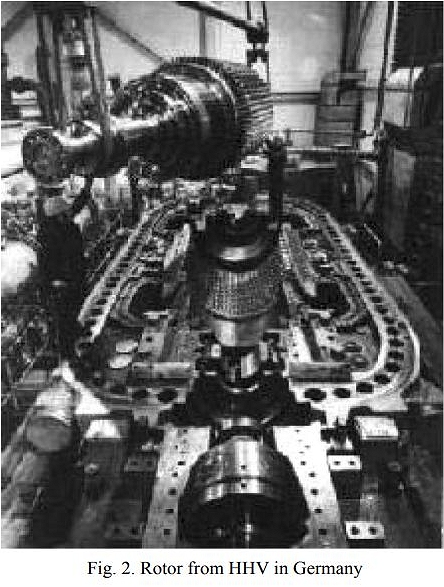

| Left: The turbine rotor of the HHV test system: Germany

|

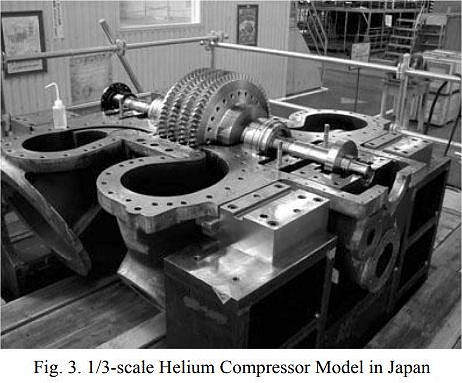

| Left: One-third scale helium compressor: Japan

|

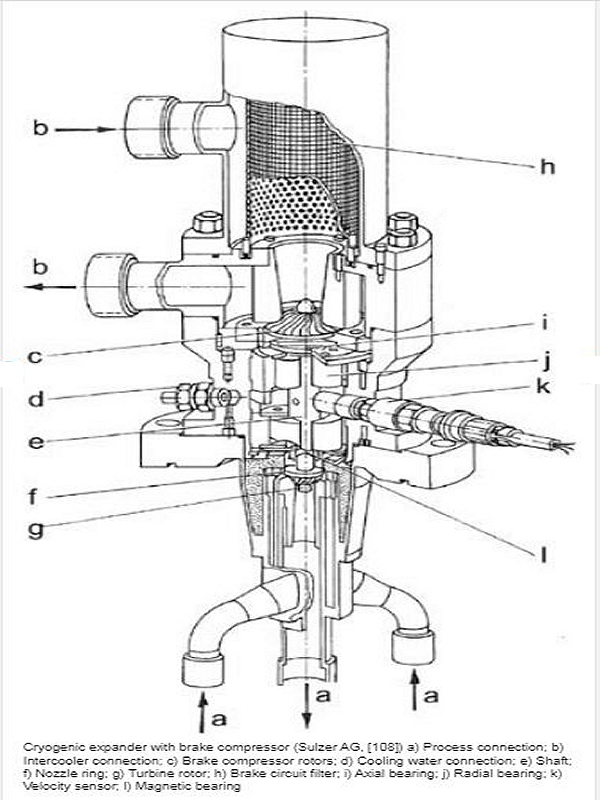

| Left: Sulzer helium turbiner

|

| Left: Helium Liquefaction Plant: France

|

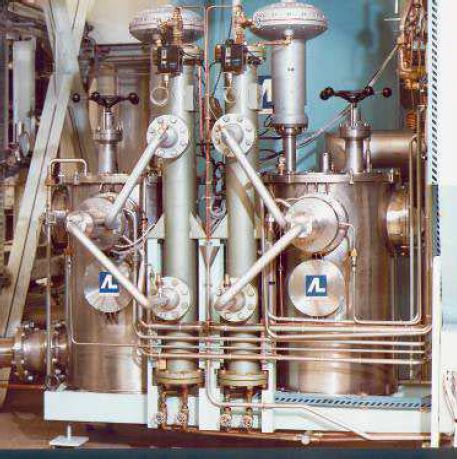

| Left: Twin Helium Turbines in Grenoble, France

|

|