The vast majority of gear wheels are wholly conventional and go about their daily rounds without fuss or bother. The extraordinary deviations from the norm that are pictured here are unusual,to put it mildly, and it is a moot point as to whether some of these drawings found a home in a real piece of machinery. If these perverse mechanical arrangements are the answer, you may need to change the question.

The drawings here are taken from the book "Mechanical Movements, Devices and Appliances" by Gardner D Hiscox, published by Sampson Low, Marston & Co in 1899. The contemporary descriptions from this volume are in quote marks.

|

| Left: Intermittent Motion Of Spur Gear: 1

"A is the driver. The pin J and the dog L are on the front side of the gear; the pin R and dog P are on the back. This class of gears may be made in varying proportion to suit the required stop motion of the gear B, A being the driver."

|

|

| Left: Intermittent Motion Of Spur Gear: 2

"In which the dogs G and F form a part of the driven gear B. This form allows of varying proportions of stop and speed motion in the two gears. A is the driving gear."

Apparently inspired by Munch's "The Scream":

|

|

| Left: Variable Sectional Motion

"...from sector gears. The sectors are arranged on different planes, so that each pair shall be matched and all so adjusted that their teeth will mesh at their proper periods."

This process of adjustment seems to have failed in the example shown here. Two ratios (green and beige) are engaged at once, which would jam the whole thing solid.

|

By now you are probably thinking that this is all so much hot air, and that no-one would ever actually attempt to make gearwheels anything like this. Wrong...

|

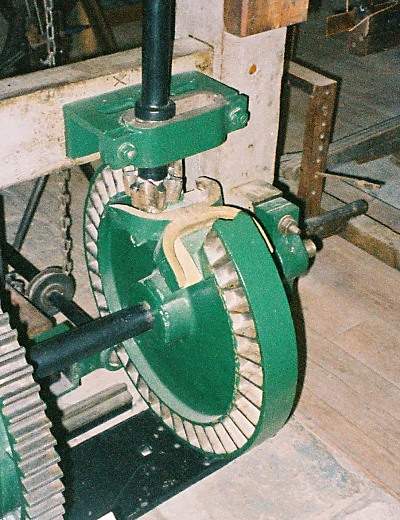

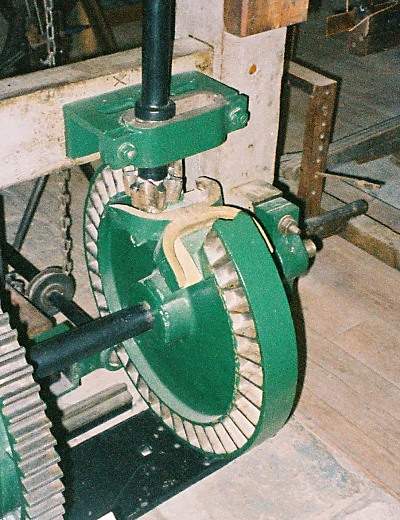

| Left: Kuhlman water pump with variable gear ratio drive: circa 1910

This is the drive mechanism of a Kuhlman water pump built in the USA, which actually exceeds in surrealism the diagrams above. Not only do the larger driven gears have a non-constant radius, but the point of engagement is shifted back and forth between the three pinions on the driving shaft. These pinions are not only different sizes, but they are also mounted off center on the shaft. As the shaft rotates the point of mesh moves sideways to meet the side shifting teeth on the large gear. According to Terry Wilson, this sort of gear was very common on early gasoline engine powered water-well pumps in the USA. It gave high speed when the pump rod was descending, and a lot of torque when it was lifting the water.

You can see YouTube videos of Kuhlman pumps working here and here and here. These videos are mildly puzzling because despite the ingenuity of the gearing the pump rods do not seem to be changing speed much between the up and down strokes. The pinions sometimes appear to be going in different directions although they are on the same shaft, but I assume this is just down to stroboscope effects in the video.

Picture kindly provided by Terry Wilson.

|

|

| Left: Hay-bailer with elliptical gears

There are dual elliptical gears on the axle above the frame, driven at a steady speed by the big gearwheel. The lower shaft has dual elliptical gears giving a variable speed, and operates the bailer arm in a quick-return movement.

You can see a YouTube video of the bailer in action here.

|

|

| Left: Hay-bailer with elliptical gears

Taken from the YouTube video linked above.

|

|

| Left:

It's not entirely clear what this machine does, but the odd-shaped gears give a quick-return action.

I think the image comes from a YouTube video. I will try to find it.

|

Here is another demonic gearwheel in real life:

|

| Left: Self-reversing gear drive on beetling machine

This remarkable gearwheel is part of the drive mechanism of a beetling machine in the Museum of Scotland, Edinburgh. "Beetling" is a process applied to linen, and cotton fabrics made to resemble linen, to produce a hard, flat surface with high lustre and to make the texture less porous; the fabric is dampened and pounded with heavy wooden mallets. You can see why a machine to do that would be a good idea- unless you were an unemployed hand-beetler, of course.

The small gear on the vertical shaft drives the large gear; after the latter has completed almost a full revolution the stub at the end of the vertical shaft encounters a curved abutment that helps guide the small gear shaft sideways so it engages with the teeth on the opposite side of the large gearwheel, which is then driven back in the reverse direction. If you look at the top of the large wheel nearest the camera there appears to be a notch at the end- in other words the end of the large wheel effectively consists of two teeth that move the small gear sideways and round the corner, so to speak. At the end of the travel the small gear swops sides again. Note the bearing just above the small gear, which allows for lateral movement.

Quite what the purpose of this forward/reverse drive was in the the beetling machine I could not determine; presumably a section of cloth needs to be repeatedly beetled.

Author's photograph

|

|

| Left: Animation of the self-reversing gear drive

Showing how the vertical shaft swings sideways to reach each side of the large wheel.

Another fine animation by Bill Todd

|

|

| Left: Demonstration model of non-circular gears in CNAM, Paris

This model was built by J Schroeder around 1860, and displayed at the Paris Exposition of 1867. The label on it says "Toothed rolling curves with frame and quadri-lobed wheels" which is more of a description than any sort of explanation. The arrangement will give a varying output speed for a constant input speed, but to what purpose?

There are dozens of similar models in glass cases, stretching down a long gallery in the museum, and this is by no means the strangest.

CNAM is the Conservatoire National des Arts et Metiers, a very fine museum. It is roughly the equivalent of the Science Museum in London.

Author's photograph. Sorry about the less than startling image quality; photographing things in glass cases is always tricky.

|

|

| Left: Square-wheel watch by Maurice Lacroix

This watch, called the " Masterpiece Roue Carree Seconde" (square seconds wheel) is a clockwork design, with the unique feature of non-circular gears to drive the seconds indication. The clover-leaf wheel is driven in the usual constant-rate fashion, but the square wheel turns slowly when its corners are engaged, and faster when it is driven via the flat sections. A non-linear scale is therefore needed on the seconds dial, much of which is obscured anyway by the square wheel and pointer on top of it.

There is, of course, absolutely no technical justification for this unnecessary complication. It is just supposed to look cool. The other little dial is an up/down winding indicator.

You can see a rather nicely done animated promotion for this watch on YouTube.

Before you condemn this as a piece of Pathological Engineering aimed at men who have far too much money, pause. This watch is in fact a one-off created and donated by Maurice Lacroix to be auctioned for the Monaco Association against Muscular Dystrophy on 23 Sept 2011, along with 40-odd other unique designs. You can read more about this and revel in the technical details at:

Worldtempus.

|

FERGUSON'S PARADOX

Ferguson's Paradox consists of three gears that are apparently driven equally, but one goes round one way, one the other way, and the central one stays still. This apparently impossible result is achieved by making the the gears the same size, but the number of teeth vary; one has one more tooth than the central wheel, and the other one less. Given big enough gears, this can be accomodated within mechanical tolerances. See it here, and here.

BIBLIOGRAPHY

|

| Left: Noncircular gears, Design and Generation

I came across this weighty tome in Cambridge the other day. Full of interesting stuff, but at a high theoretical level and with some pretty advanced mathematics.

From Cambridge University Press. You can get it from Amazon

|

LINKS

The links to odd-gearwheel sites that were previously displayed here have been removed as they have all been taken over by dodgy ad sites. If you stored these links then lose them.

Typing "non-circular gears" into the search function of Youtube yields a large number of videos of weird gears squirming around in unsettling ways. Some examples:

Here is one example, 13 years old.

Here is a tutorial on the design of elliptical gearwheels, from Gearotic Thoughts.

There is a wooden non-circular planetary gear fidget spinner here.

The Gear Head is really quite something.

The gears involved may be nothing special, but who can resist a Mechanical Turing Machine made of wood?

Here's a page from Popular Mechanics on odd gears. Most of it seems to have come straight off YouTube.

The Do-nothing machine has some non-circular gears. The machine is at the Craftsmanship Museum, Carlsbad, CA.