Updated: 8 Jan 2014

Early history added

Updated: 8 Jan 2014

|

|

It was not. There was (as usual) a good reason. In fact, it was actually a pretty clever solution to a temporary problem.

| Left: Article from The Electrical Magazine: 1904

|

The article above shows that the possibility of using hydro-electric power to boil water in a locomotive had ben considered for a long time. The article's date is only known to be between January and June 1904.

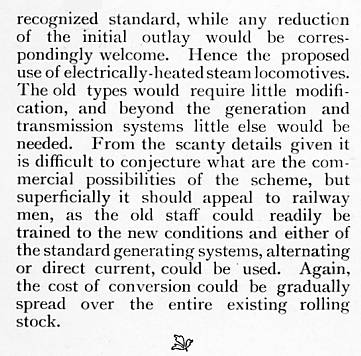

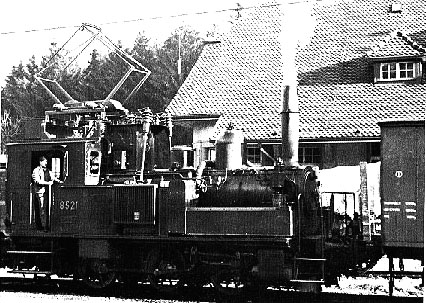

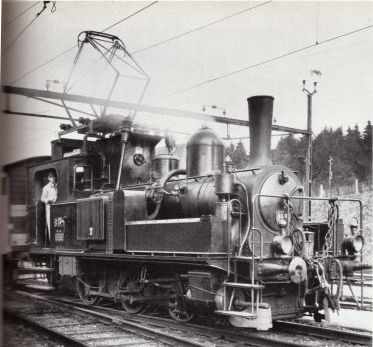

| Left: One of the Swiss electric-steam tank engines

|

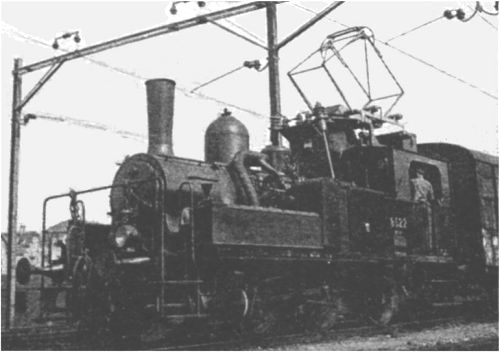

| Left: Another view of the electric-steam tank engine

|

| Left: And another view. The chimney seems to have been extended in this photo

|

| Left: This is engine E 3/3 pictured in 1942. |

| Left: This was clearly taken at the same time as the picture above. |

| Left: Preserved, without electric heaters

|