This page resulted from the simple act of going into a railway bookshop in Paris, next door to the Gare St Lazaire. Such places open new worlds of strange machinery that are probably never going to be described in English.

France is a fascinating environment for the connoisseur of the vertical boiler. The population of France is a good deal more spread out than the population of Britain, and before the widespread use of motor transport, this led to the development of an extensive secondary rail network, lightly constructed and with gauges varying from 600mm to 1m.

After a slow start, in 1914 the French railway system had become one of the densest and most highly developed in the world, and had reached its maximum extent of around 60,000 km (37,000 miles). About one third of this was made up of narrow gauge secondary lines.

However, many secondary lines located in rural areas quickly fell into deficit, and some never reported a penny of profit in their history. Lines were built to fulfil election promises in regions without industry, and only a small amount of agricultural trade. Since they were built at minimum cost they tended to follow the landscape, and therefore had steeper gradients and tighter curves than the mainline railways; they were not built for speed. This is true of many lines of western France, Vendée and Brittany, but also in the highlands of the Massif Central, and in the Alpine valleys. When these local railways became insolvent they were usually absorbed by the nearest main-line railway company, though this did not alter their lack of profitability.

By the 1880s, it was clear that these little single-track lines could not be operated economically with conventional trains, and there many projects that attempted to solve this by integrating the locomotive with a single carriage. A whole train was reduced to a single vehicle with its own engine, compartments of different classes and a luggage van section. A vertical boiler was normally used as it could be mounted on a compact two-axle chassis with a short wheelbase, allowing the sharp curves to be negotiated, and could be fired by the driver, usually by lifting a door in the coal bunker and allowing coal to fall into the grate; no shoveling was required. At the slow speeds of the secondary railways the driver could afford to spare the boiler some of his attention.

While investigations are continuing, it appears that all these lines used two-man operation; a driver/fireman, and a conductor/guard who collected the fares. Presumably most of the stations were unmanned for economy.

VERTICAL BOILER LOCOMOTIVES OF THE PARIS-ORLEANS RAILWAY (PO)

Some information on the Paris-Orleans Railway.

|

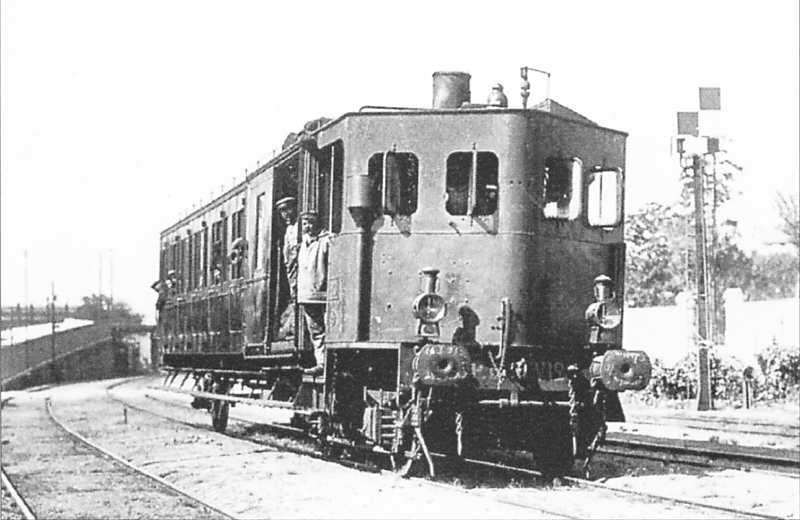

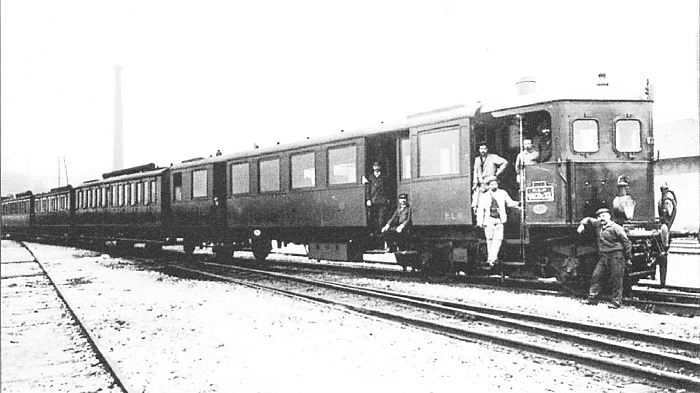

| Left: AV12 vertical-boiler locomotive: 1905

Pictured at Bourges. (Cher) This is one of two locomotives built with Purrey vertical boilers for the PO by Robatel & Buffaud (Wikipedia page in French) of Lyons in 1905.

Valentin Purrey of Bordeaux were leading manufacturers of steam lorries, and specialised in vertical boilers.

|

The distinctive front-end design is reminiscent of the early wind-splitting locomotives of the early 1880's, which had sharp-edged front ends in an attempt at streamlining. This was still a current fashion when the Thuile locomotive (with a distinctly sharper cutting-edge) was built in 1900. It seems unlikely that anyone thought that streamlining was going to do any good at the very modest speeds at which these vertical-boilered vehicles travelled; probably it was just fashionable.

On the left of the cab front (our left) is a big funnel presumably used for refilling the water tank. On the top of the roof at the right, next to the whistle, is the chute through which coal was dropped into the bunker.

|

| Left: AV12 vertical-boiler locomotive: 1905

|

VERTICAL BOILER LOCOMOTIVES OF THE PARIS-LYONS-MEDITERRANEAN RAILWAY (PLM)

Some information on the Paris à Lyon et à la Méditerranée Railway.

THE VACf LOCOMOTIVES

|

|

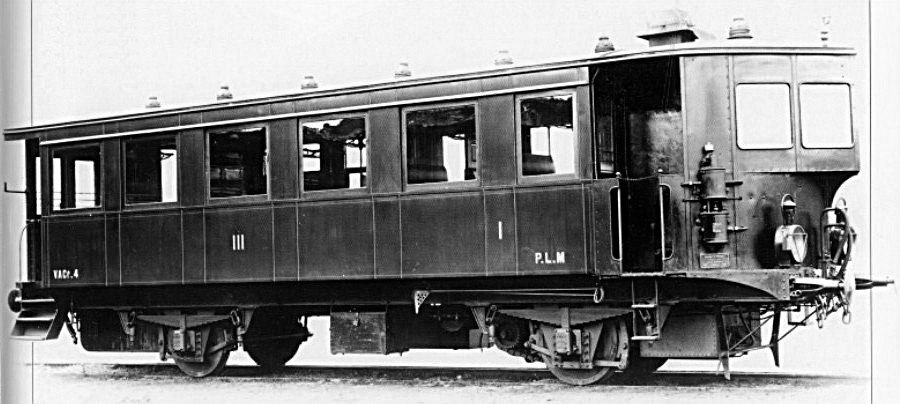

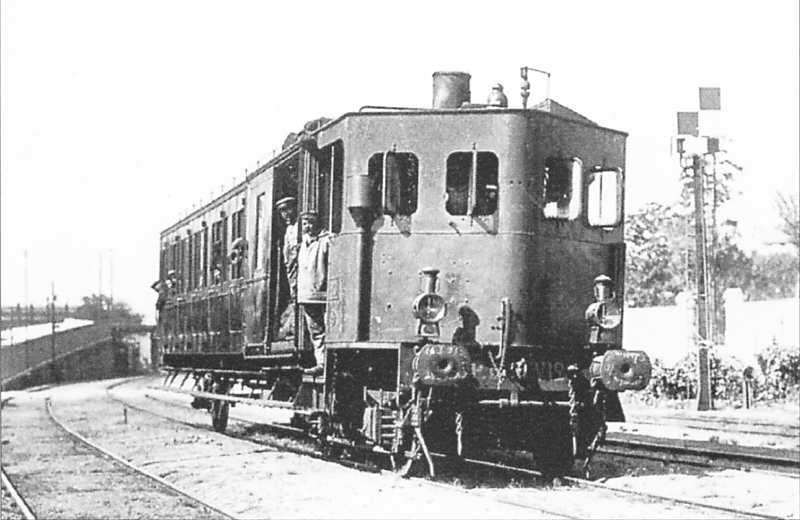

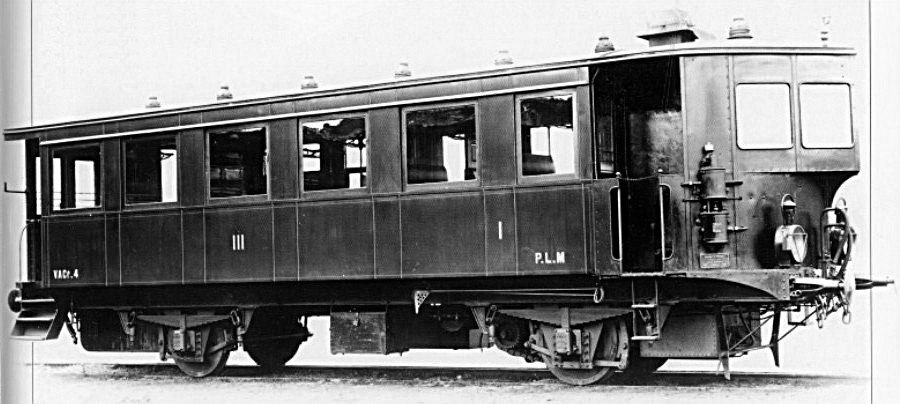

Above: VACf Number 4 of the PLM, with its strangely gothic wind-splitting bow, and a square chimney with an odd valance attached

|

In 1901 PLM placed an initial order with Purrey for two new railcars for secondary lines. The spec required the transport of 30 to 35 seated passengers, including 8-10 in first class. An incline of 1:50 had to be taken at 20 km/h minimum, with a normal speed of 60 km/h on the level. 60 km had to be covered without coaling. and 30 km without taking water. The two Purrey railcars were tested on the Alès-Ardoise line and showed definite promise, especially as regards fuel economy.

In 1905 four more VACf locomotives were delivered, numbered 3 to 6 and are virtually complete trains. Apart from the driving position, there was a compartment for the conductor, 4 Third-class compartments, a closed access platform with seat 1 'and 3' class, all lit and heated.

They spent their careers on small lines south of the Massif Central, Jura or Burgundy, with or without trailers. (The temptation to aid trailer-coaches to this sort of vehicle seems to have been virtually irrestistible; predictably the combination almost always proved under-powered) These locomotives were taken out of service in the late 1920s when railcars powered by internal combustion engines appeared. The new machines were more convenient, starting immediately without time for raising steam, and not requiring boiler cleaning.

12 passengers were carried in 1st class, and 36 in 3rd class.

The VACf locomotive was powered by a compound engine having two high-pressure and two low-pressure cylinders.

Some facts:

Boiler pressure20 kg/cm² (284psi)

Grate area0.82 m²

HP Cylinders140 x 200 mm

LP Cylinders200 x 200 mm

Weight27 tonnes

Length12.4 metres

Speed 60 km/h

| | | | | | | | | | | | | |

|

| Left: VACf vertical-boiler locomotive: 1905

|

THE VACDf LOCOMOTIVES

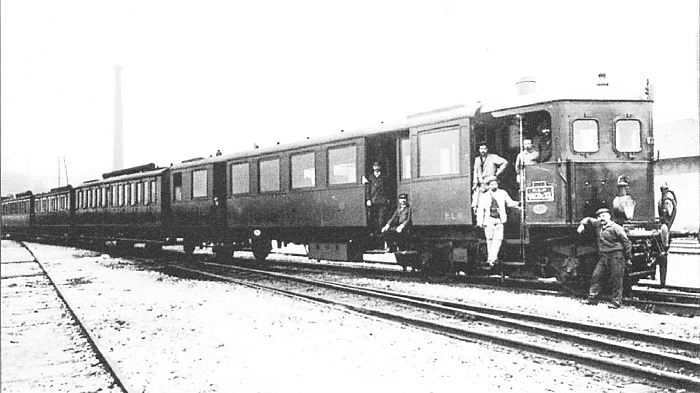

A series of 13 of these Purrey-boilered locomotives were built by Buffaud Robatel, and delivered to the PLM in 1904. They were numbered from 23 to 35. They weighed 38 tonnes and had room for 12 passengers in 1st class and 47 in 3rd class. On trial they were able to pull five carriages (92 tonnes) at 65 km/hour.

|

| Left: VACDf No 31 of the PLM

|

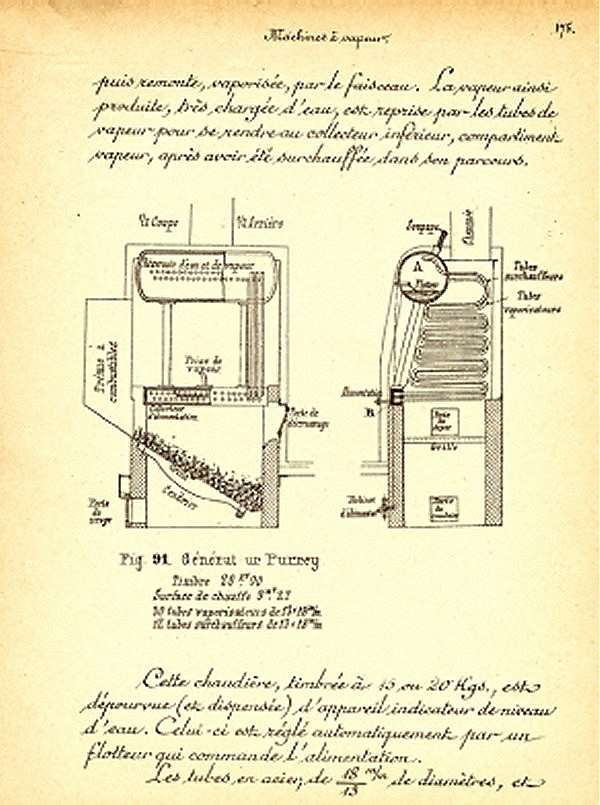

THE PURREY BOILER

The Purrey boiler was patented in Britain by Valentin Purrey (of 97 Rue St-Lazare, Paris). The patent number was 26,904 and it was granted in 1899.

|

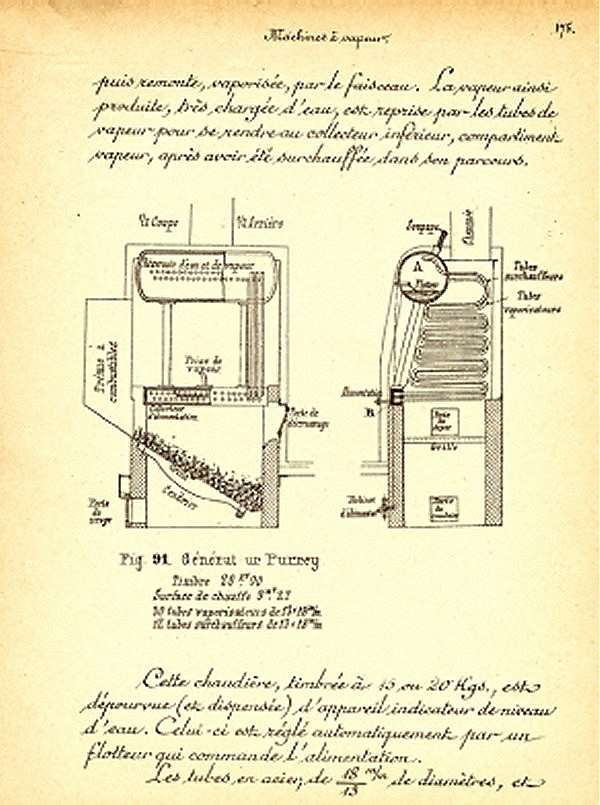

| Left: The construction of the Purrey boiler

The Purrey boiler was of the water-tube type. At the top is a conventional steam drum. At the bottom is a rectangular box divided in two; one section acts as a water-drum, while the other collects steam after it has been superheated in the tubes a1.

- a: Boiler tubes

- a1: Superheater tubes

- b: Steam drum

- c: Feed collector (equivalent to lower drum)

- d: Water return pipes

- e: Protective sheath over lower boiler tubes

- f: Metal boiler casing

- h: Screen to prevent combustion gases reaching water return pipes d directly

- S: Safety valve on steam-drum

- V: Steam out to engine

The patent illustration appears to show a stationary boiler, as the furnace appears to be constructed of brick.

There is more information on the boiler in the article below.

Image from British patent 26,904, granted 1899

|

THE PURREY CAR (PARIS-ORLEANS RAILWAY)

The information below, on the general use of Purrey-derived locomotives, is from The Transactions Of The Amer1can Society Of Mechanical Engineers, Volume 29 (1907). It probably refers to the AV12 illustrated above.

"Numerous experiments have been made on the different French railways, including the Paris-Orleans; Paris, Lyons & Mediterranean; Northern; Western and the State railways, with various types of cars, but the most successful at the present time, and the one being almost universally adopted, is that of Purrey, of Bordeaux, and although differing in minor structural details, the power plants of the Purrey cars as built for the different railways are practically the same. There is also a slight variation in the size, weight, and arrangement of cars to meet best the requirements of the different roads, but that of the Paris-Orleans Railway is fairly representative of all the cars used in France.

"The car body has a total length of about 60 feet, and seats 30 third-class passengers in three compartments, and 25 first-class passengers in 2 compartments. In addition to this, there is a baggage compartment at the forward end 11 feet 6 inches long and extending the entire width of the car, 112 inches. The forward end is pivoted on a power truck, the rear end being carried upon a single axle. The power truck, which carries the boiler, motor, fuel, water, etc., has two axles 126 inches apart, the rear wheels only being used for driving. The weight of this truck is 14 tons, of which about 7 tons is on the rear axle. The total weight of the car complete is in the neighborhood of 35 tons.

"An inclined grate is provided, and the fuel (coke) feeds from the bunker attached to the side of the boiler, automatically, or practically so, the only attention necessary on the part of the driver being to regulate the supply by means of a vertical sliding door, operated by a lever, at the point where the bunker communicates with the furnace. Where price is not prohibitive, kerosene might be used to advantage, and would permit more perfect control of fire, and thus avoid burning out tubes.

"An arrangement is provided for automatically maintaining a constant water level, consisting of a float inside the upper drum connected through a stuffing box to a valve in the steam line running to the feed pump, the idea being that as the level of the water is lowered, the steam valve opens and the pump supplies water until the level has reached that point at which the float closes the steam valve. This was found to be very unsatisfactory as the stuffing box, if made tight enough to prevent leakage, created so much friction that the apparatus would not work. It was therefore necessary to depend upon the driver to maintain a correct water level, Blake double acting feed pumps being provided for this purpose.

THE PURREY BOILER

|

| Left: The construction of the Purrey boiler

"The Purrey boiler is tubular, its general construction being illustrated by Fig. 3a and 3b. Two drums are provided, the lower one of rectangular section and made of cast steel, the upper, cylindrical and of cast iron. The lower drum is divided into three compartments, two of which are provided for water, the third for superheated steam. The outer and lower compartment is connected with the upper drum by two large return pipes. It is also connected with the intermediate compartment of the same drum by 41 U shaped tubes.

"The feed water entering the lower compartment is thus heated in passing through these tubes, which are in direct contact with the flame. From this point, the water rises through a series of U shaped tubes to the upper drum, and the steam thus formed is returned from the upper drum, in which the water level is maintained at about the median level, through a number of similar tubes to the third compartment of the lower drum, from which it is taken to the motor. The steam is highly superheated in these tubes, the average temperature of superheat being from 750 to 900 degF. At first, considerable trouble was experienced with the burning out of the superheater tubes in the lower coils which were in the most direct contact with the flame. This difficulty was overcome by eliminating two coils and increasing the thickness of the tubes at that point. Originally all tubes were 2 mm. thick, but those referred to were increased to 3 mm.

Note: this diagram of the boiler does not come from the ASME Transactions article.

|

THE MOTOR

"The motor is 4-cylinder tandem compound, high pressure 6 inches diameter, low pressure 8 inches diameter, and the stroke 8 inches, rated at 260 horse power at 650 revolutions per minute. A bypass valve is provided to admit high pressure steam to the low pressure cylinders for quick acceleration and unusually heavy pulling. Ordinary D type valves are used, operated through Stephenson link motion.

"In this design, the motor is attached horizontally to the frame of the car, and its power transmitted to the rear axle by two toothed chains of special construction, similar to the Renold and Morse silent type. All the working parts are enclosed in a dust proof case, and lubricated principally by splash. The motor is accessible through a trap door in the floor of the baggage compartment, and any ordinary adjustments can be made from this point. A door is also provided opening into the baggage compartment through which the boiler tubes may be inspected, thus rendering the most delicate parts of the mechanism readily accessible. Should it be necessary to overhaul the boiler or motor, the power truck may be removed from the body of the car in 20 minutes and another substituted in its place. Westinghouse air brakes and hand brakes are used. A steam whistle is provided.

USAGE

"The Paris-Orleans road have 10 cars and 12 power trucks, and have been able to keep the 10 cars in service practically all the time by having the two extra trucks in reserve. Replacing boiler tubes is a comparatively simple matter. By removing plugs in the two drums on the opposite sides from where the tubes enter, the tubes are accessible either for driving out or expanding.

"As a rule, one or two trailers are attached to these motor cars, the average weight of the train being 50 tons. The fuel consumption for such a train is about 21 pounds of coke per mile. This car is arranged to run in one direction only, except for backing up, and the crew consists of only the driver and one man in the baggage compartment, tickets being taken at the stations by inspectors. It is geared rather high, and is capable of running at a speed of about fifty-six miles per hour. Its acceleration, however, is not so good as that of the Great Western car.

"The Orleans road has instituted a motor car service between Bourges and Saincaize, a distance of 59 kilometers (37 miles), the run being made in 70 minutes, including eight stops. Sufficient fuel and water capacity are provided for a run of 50 kilometers. The cost of operation per train mile is about 7 cents, itemized as follows, the train weighing approximately 50 tons:

"Fuel (coke) $0.0355, Kindling wood 0.0013, Oil 0.0022, Water 0.0005, Repairs 0.004, Driver's wages 0.0264: Total 0.0699.

"This of course does not include the wages of the guard, nor any of the overhead expenses. It is probable, however, that the cost of operation of this car is somewhat less than that of the Great Western.

"The Purrey system has been used for a number of years on different tramway lines in the city of Paris, but for this service it has been found that the single expansion engine gives better results than the compound, and also that there is no advantage in having a variable cut off, owing to the frequency of the stops, the speed of the motor being controlled entirely by the throttle valve.