Updated: 5 May 2003

Flexible-Boiler Mallet Locomotives. |

Updated: 5 May 2003

|

The loco above is a straightforward non-flexible but semi-articulated Mallet locomotive. The front 8-wheel section has a bearing roughly under the first boiler dome.

THE BELLOWS-BOILERED MALLET

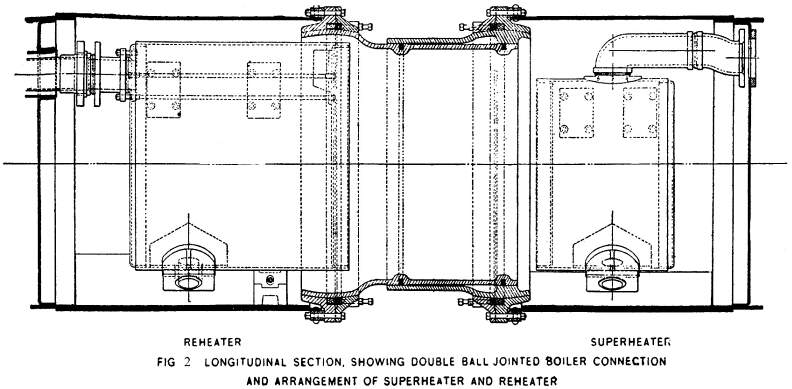

If you persist with long boilers, eventually they hang out too far on curves, so the obvious answer (to some people) is to make the boiler bend in the middle, either with a ball-joint, or- believe it or not- metal bellows. The idea originated with Samuel Vauclain of the Baldwin Locomotive company in 1910, and was prompted by the discovery that the combustion gases were no longer transferring heat to the water by the time they were some 22 feet ahead of the boiler. This was the secret to making this apparently lunatic notion work- the actual boiler stops before the flexible section, so the joint is not under steam pressure, but simply passes hot gases through to a superheater, a reheater for the LP steam going to the front cylinders, and a water preheater, in the front section.

No, really, I'm not making this up. Just to prove it...

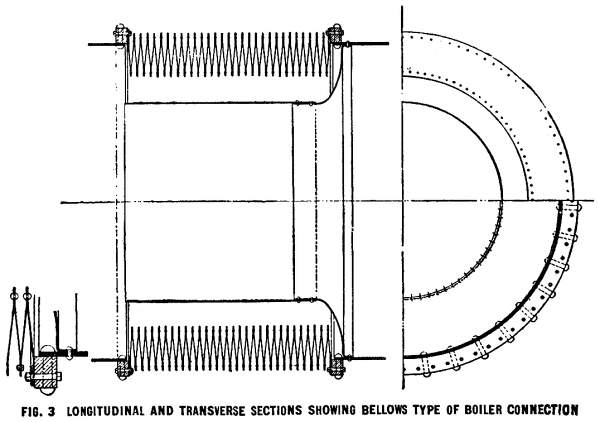

...Here is an engineering drawing of the bellows part. The bellmouth structure in the middle presumably keeps the hot combustion gases away from the bellows.

The bellows was made of fifty rings of resilient steel, riveted at the inner and outer edges.

The Santa Fe railroad bought six of these 2-6-6-2 locomotives from Baldwin over a two-year period, hoping they would ride more easily than the long rigid locomotives they were intended to replace. This proved not to be the case, and of course... there was trouble with the bellows.

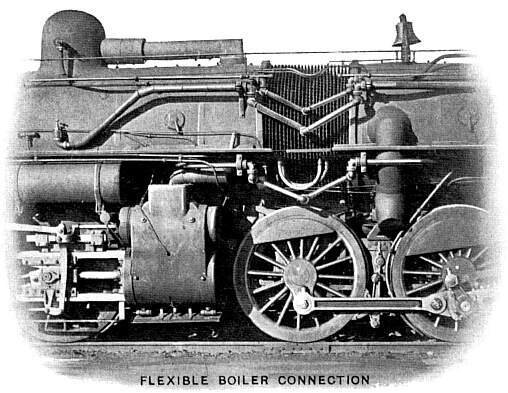

| Left: A close-up of the bellows. Note all the hinged pipes and flexible hoses required.The bellows worked- until cinders built up between the folds, and when they tried to close up on the inside corner of a curve, the outer riveting burst apart. |

THE BALL-JOINT MALLET

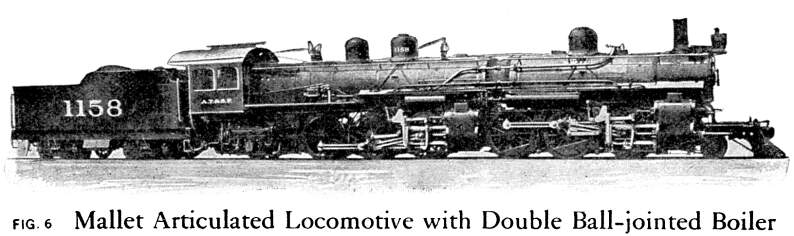

To cure the problem of the bellows , they were replaced with huge ball-joints. This worked, but did nothing to help the poor riding, and the locomotives were retired from use in the mid 1920's.

This may appear no more plausible...

...So here is a drawing of the ball-joint part.

There is nothing bizarre about articulated locomotives- thousands were built and operated successfully. Bendable boilers, however, appear to be just asking for trouble, and were very much a one-off.

|