The Arnold Electro-Pneumatic system used the compression and expansion of air to implement a form of regenerative braking on electric rail-cars, and also control the synchronous electric motors fitted. On going downhill, air was compressed and stored in tanks under the car. When required, the stored air was released back into the compressor cylinders, which then acted as a motor to assist the electric drive. Bion J Arnold (1861-1942)was President of the American Institute of Electrical Engineers, and had an impressive record as a rail engineer; he was not a lone eccentric. He is sometimes called "the father of the third rail".

All the details here come from Electrician magazine, netween January and June 1904.

|

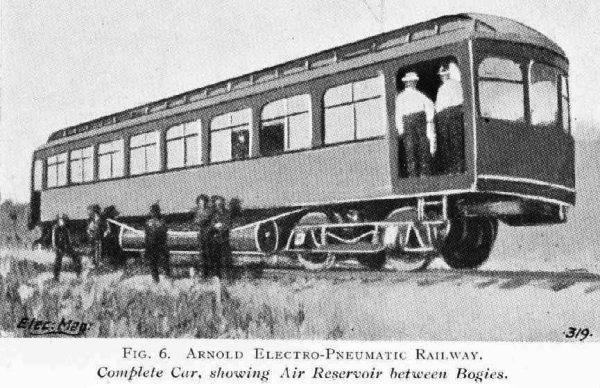

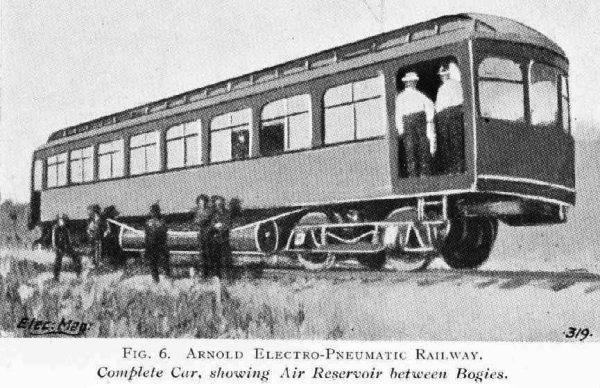

| Left: The Arnold Electro-Pneumatic car: 1904

A compressed-air tank can be seen under the car body.

There is no sign of overhead wires, so presumably power was picked up from a third rail.

|

The machine was completed by 17th December, (presumably in 1903) but the next morning it was destroyed by fire, along with two other cars. With that sort of timing, you can't help wondering if somebody really didn't like Mr Arnold.

|

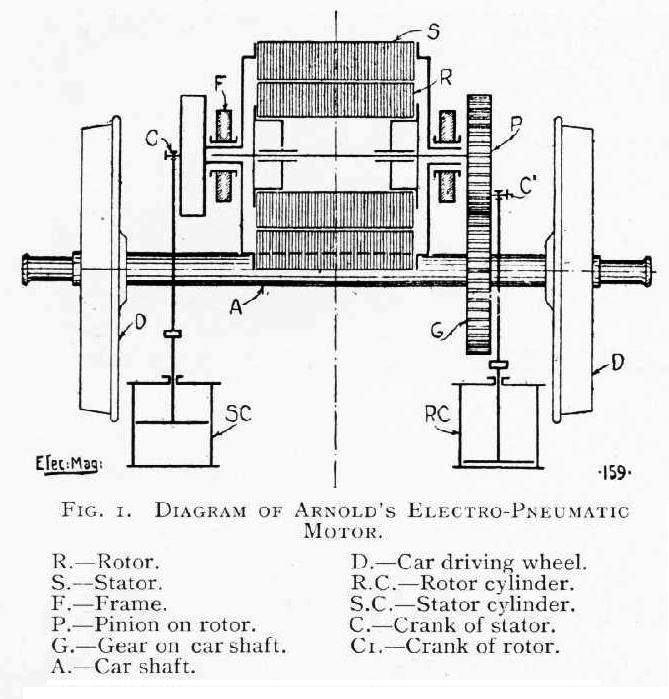

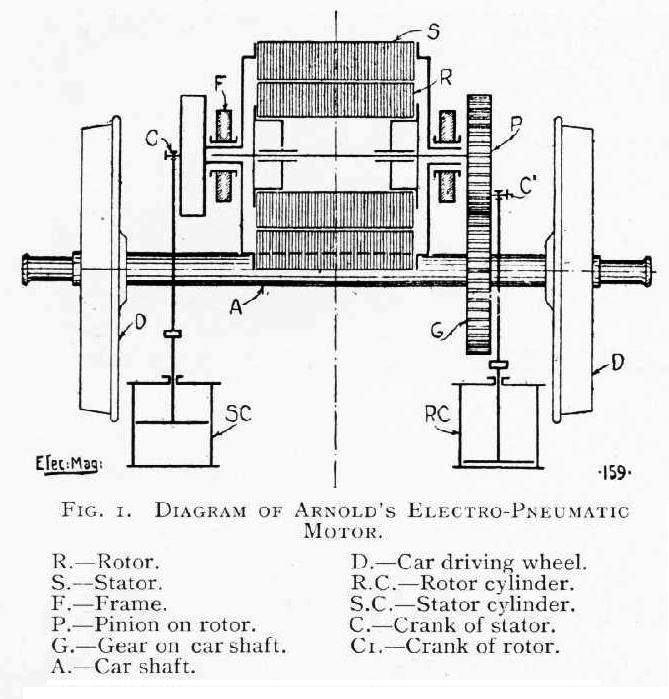

| Left: The Arnold Electro-Pneumatic System: 1904

The electric motot rotor and stator rotated in opposite directions.

|

A synchronous electric motor can normally only run at one speed, set by the frequency of the supply, but here the rotating "stator" (if you see what I mean) gave variable speed control when compressed air was shunted to and fro between the two cylinders. This would have been inefficent due to the heat lost when compressing air, and it is very doubtful if it would have been better than resistance-control of conventional non-synchronous motors. There were certainly a lot more moving parts.

|

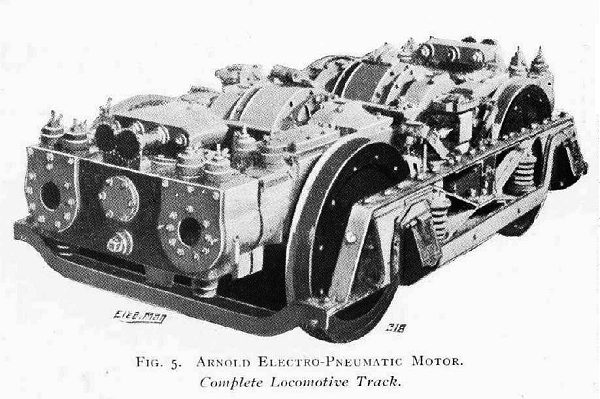

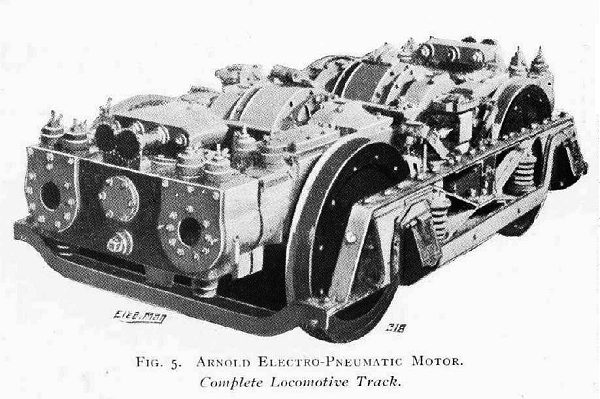

| Left: Complete bogie with electric motors and air compressor/motors: 1904

|

|

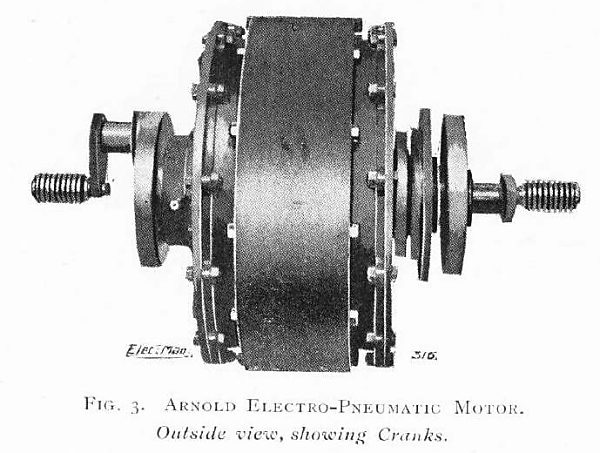

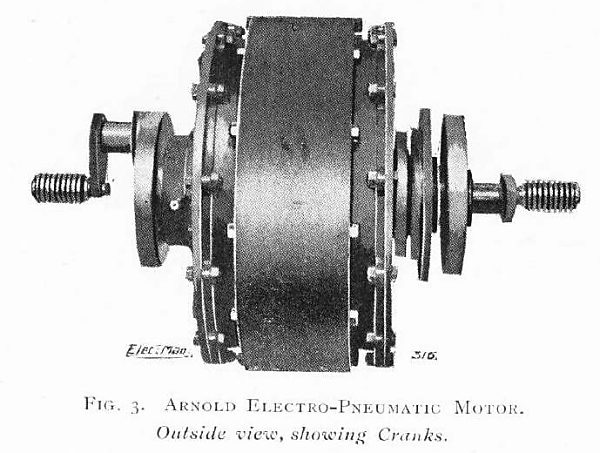

| Left: External view of an electric motor: 1904

The compressor/motor cranks can be seen at the end of the central shaft.

|